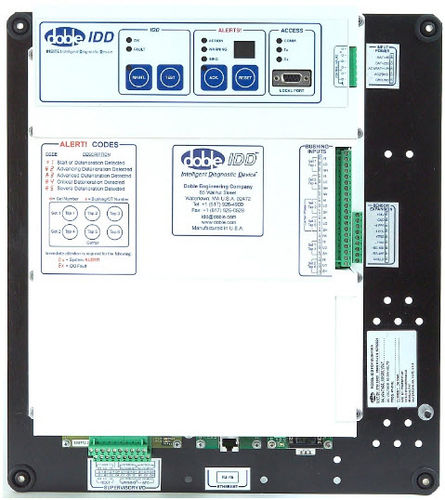

Electrical appliance diagnostic system IDD

Add to favorites

Compare this product

Characteristics

- Options

- electrical appliance

Description

Doble's Intelligent Diagnostic Devices (IDDs) are a cost-effective online diagnostic system used to monitor electrical apparatus in the field. Each IDD is intended to be apparatus-specific and can be mounted in existing enclosures or in optional enclosures available from Doble. The IDD is easy to install and, once configured, operates continuously.

Application:

Continuous on-line monitoring of bushing Power Factor/Tan Delta and capacitance via test tap. May also be used for hydrogen and/or moisture in oil via Doble or third party sensors.

Doble IDD versions:

• IDD for Moisture in Transformers

• IDD for Dissolved Gas in Oil Analysis (DGA)

• IDD for Bushings and CT's

Features and Benefits:

• Continuous Condition Assessment. The status of the equipment is constantly being evaluated by the field-proven Expert System, minimizing the need to perform routine testing.

• Early Identification of Problems. Refined signal processing and field-proven analysis identify abnormalities, anticipate failures, and eliminate false alerts.

• Prioritized Alerts. Based on the significance of the incipient problem, the analysis issues an alert indicating the criticality of the problem, providing a tool to manage risk.

• Specifies Corrective Action. An alert identifies the problem and prompts corrective action.

• Simple Installation. The IDDs is a self-contained device that requires only connecting sensors, input power, and optional remote communication to complete the installation with minimum outage time and resources.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.