- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

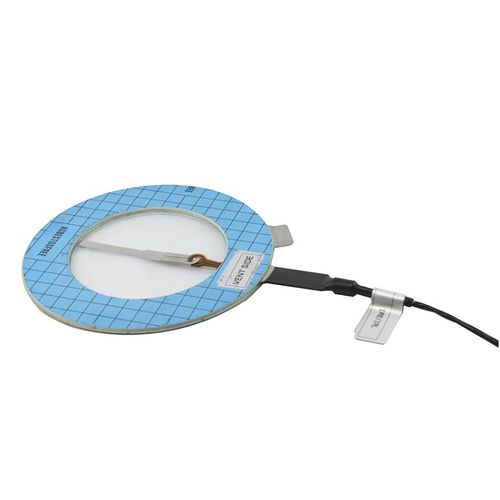

Rupture disc alarm annunciator IRL

Add to favorites

Compare this product

Characteristics

- Options and accessories

- for rupture disc

Description

DonadonSDD IRL rupture sensors are simple and efficient instruments for recording the bursting of a rupture disc.

The detector is installed between the container on the discharge side and the flange downstream from the safety device replacing the traditional seal. The alarm indicator cables are connected to the plant safety system with an intrinsically safe barrier that conforms to the electrical characteristics of the sensor (max voltage 24V DC and max current 50 mA) and the hazardous area classification.

The detector is composed of an electric sensor simply mounted on a target made up of:

a stainless steel ring

a PTFE membrane

seals: standard aramid fibre available also in graphite, PTFE

When the disc bursts, the copper circuit of the IRL alarm system opens and as a result of this the flow of current is cut off, allowing the connected equipment to signal that the disc has opened.

The IRL sensor also detects any rupture disc leaks thanks to the non-perforated membrane.

The IRL sensor is classified as “basic electrical material” and is certified according to European Directive 94/9/EC (ATEX). Zone installation depends on barrier type:

Ex ia barrier --> zone 0; 20; 1; 21; 2; 22

Ex ib barrier --> zone 1; 21; 2; 22

Installation must be according to standard EN 60079-14.

Operating temperature - From -20°C up to +265°C (depending on the seal used)

Encapsulating membrane - Polyimide (Kapton®)

Printed Circuit - Copper

Max supply voltage - Copper

Max supply current - 50 mA

Cable - Standard, 2 m

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.