- Machine-tools

- Machining Center

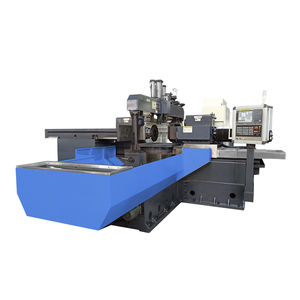

- 4-axis CNC milling machine

- Dongguan Gooda Machinery Manufacturing Co., Ltd.

2-spindle CNC milling machine TH-1200NCA4-axishorizontalfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- horizontal

- Machined material

- for aluminum

- Number of spindles

- 2-spindle

- Associated functions

- cutting

- Certifications

- ISO 9001

- Applications

- for the automobile industry, for the aeronautical industry, for the mold industry, for large workpieces, for model making, for molds, for heavy-duty machining, for aluminum profiles, for sheet metal

- Other characteristics

- high-speed, high-power, CE, high-power, conveyor belt, with automatic tool changer

- X travel

525 mm

(20.67 in)- Y travel

525 mm

(20.67 in)- Z travel

1,800 mm

(70.87 in)- Rotational speed

Min.: 50 rpm

(314 rad.min-1)Max.: 500 rpm

(3,142 rad.min-1)- Power

15 kW, 18.5 kW, 22 kW

(20.39 hp, 25.15 hp, 29.91 hp)- Table rotation (C axis)

360 °

- Work feed X-axis

8,000 mm/min

(5 in/s)- Work feed Y-axis

8,000 mm/min

(5 in/s)- Table load capacity

4,000 kg

(8,818 lb)- Weight

13 t

(14.33 us ton)- Overall length

5 m

(16'04" )- Overall width

5 m

(16'04" )- Overall height

2.6 m

(8'06" )

Description

CNC twin head milling machine TH-1200NCA

CNC twin head milling machine (also known as CNC duplex milling machine) efficiently removes chips from two sides at the same time. This process produces square blocks with accuracy as +/-0.01mm while reducing machining costs by 50% or more. We offer the premier solution on mold steel preparation. With FANUC controlled system, CNC duplex milling machine can square virtually any size blocks. Let us help you do more, with less, so your operator can “Load, Lock and Go” by placing workpiece against location pins. It will be automatic measure/ tool-setting, automatic tool division and automatic connection cutting, automatic rough cutting and finish cutting.

Productivity benefits

GooDa CNC twin head milling machines offer the following benefits:

1.has obtained dozens of patent technology and software copyright, and has successively passed the ISO 9001 quality management system certification and CE product safety certification of the European Union TUV certification, national high-tech enterprise evaluation and other honors.

2. After sale service, deliver high reliability with an emphasis on efficient maintenance service all the time. Maintain part-to-part consistency. we will help you at once when there is a problem. Besides, we will check machine regularly.

3. Machines come wired for USA electricity or your local electricity.

4. We supply expert installation and training.

5.Save you time and money and increase your productivity by milling your tools two sides at once.

6.6. Maximize tool life assuring your production will pay dividends for many years.

Don't worry and trust us, we will all here service for you

Other Dongguan Gooda Machinery Manufacturing Co., Ltd. products

CNC Duplex Milling Machine

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Drilling machine

- Milling CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Horizontal CNC machining center

- Drilling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.