- Machine-tools

- Machining Center

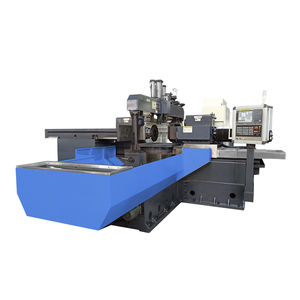

- 4-axis CNC milling machine

- Dongguan Gooda Machinery Manufacturing Co., Ltd.

2-spindle CNC milling machine TH-1600NCA4-axishorizontalfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- horizontal

- Machined material

- for aluminum

- Number of spindles

- 2-spindle

- Spindle mount

- BT 50

- Other characteristics

- high-speed, high-precision, CE, high-power

- X travel

660 mm

(25.98 in)- Y travel

660 mm

(25.98 in)- Z travel

2,140 mm

(84.25 in)- Rotational speed

Min.: 50 rpm

(314 rad.min-1)Max.: 300 rpm

(1,885 rad.min-1)- Power

22 kW, 30 kW, 55 kW

(29.91 hp, 40.79 hp, 74.78 hp)- Workpiece max height

430 mm

(17 in)- Table rotation (C axis)

360 °

- Work feed X-axis

8,000 mm/min

(5 in/s)- Work feed Y-axis

8,000 mm/min

(5 in/s)- Table load capacity

10,000 kg

(22,046 lb)- Weight

21 t

(23.15 us ton)- Overall length

8,000 mm

(315 in)- Overall width

7,000 mm

(275.6 in)- Overall height

2,650 mm

(104.3 in)

Description

TH-1600NCA

The best choice of surface roughing to finishing milling machine for 420-1600mm flat steel.

Apply for:

Cold work steel

Tool steel

Construction steel

Finished product:

Planimetric accuracy ≤0.01mm/300mm (0.02mm/1000mm)

Squareness ≤0.01mm/300mm

Roughness Ra 0.6-1.25um

Productivity benefits

1. Automatically measure, automatically processing and excellent surface performance.

2. Patented automatic rotary worktable make sure roughing and finishing processing go ahead automatically, reduce working strength of operator and increase productivity accordingly.

3. Maintain high accuracy for dimension, squareness and parallelism.

4. One loading and one setting needed only is helpful to shorten the preparation time.

5. This model goes well with steel bar processing also.

VIDEO

Other Dongguan Gooda Machinery Manufacturing Co., Ltd. products

CNC Duplex Milling Machine

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Drilling machine

- Milling CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Horizontal CNC machining center

- Drilling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.