- Metrology - Laboratory

- Metrology and Test Equipment

- Metal pendulum impact tester

- DONGGUAN ITM-LAB MACHINE INC.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

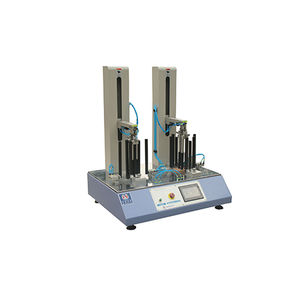

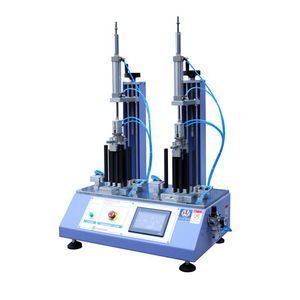

Charpy testing pendulum impact tester RS-8217for metals

Add to favorites

Compare this product

Characteristics

- Applications

- for Charpy testing, for metals

Description

This machine is applied to testing impact resistance property of metal materials under dynamic load, to judge material impact toughness value under dynamic load. One operation cycle of this machine includes pendulum rising, latch withdraw, impact, auto swing and energy display. Pendulum rise automatically after impact specimen for the next impact test. It adopts PLC control and LCD display. It is convenient for reading and operation, high efficiency and high security. It can better show its superiority for continuous large number of impact test on metallurgy researching and in test room of mechanical manufacturer.

Standard

• 1.National standard: GB/T3808-2002 Test method of pendulum impact testing machine;

• 2.International standard: ISO83-76 steel charpy (U notch) impact test;

• 3.International standard: ISO148-83 steel simple beam (V notch) impact test.

Basic structure

This impact testing machine is composed of base, framework, pendulum, dial indicating device, drive mechanism, pendulum hanging mechanism, safety device, electric device control section, energy measuring, control system and data processing system.

Basic configuration

• 1.Host machine: including base, framework, pendulum, dial indicating device, transmission mechanism, pendulum hanging mechanism, safety device, bearing jaw and optical-electricity encoder (Japanese LINE).

• 2.Pendulum: 300J, 150J, each is one piece.

• 3.Electric device control segment: one set, with auto control function for manifold cycles of taking pendulum, impacting, swinging pendulum and impacting again.

• 4.Energy measuring and control system plus data processing system: one set, LCD display rising angle, angle and energy.

Catalogs

Other DONGGUAN ITM-LAB MACHINE INC. products

Impact and Drop Testers

Related Searches

- Test machine

- Test cabinet

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Compression test machine

- Climatic test chamber

- Vertical test machine

- Humidity test cabinet

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Digital testing system

- Industrial testing system

- Precision test machine

- Stainless steel test cabinet

- Environmental test cabinet

- Plastic test machine

- Automobile test cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.