- Machine-tools

- Machining Center

- 3-axis machining center

- Doosan Infracore Machine Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

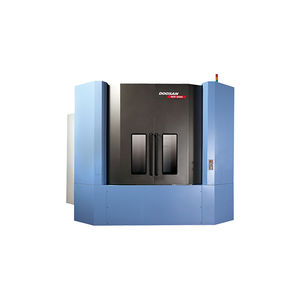

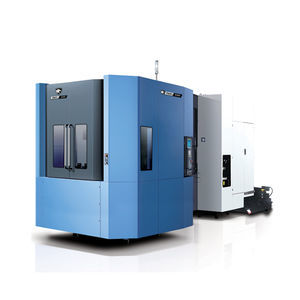

3-axis CNC machining center Mynx 5400 series verticalISO 50milling

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- ISO 50

- Associated functions

- milling

- Applications

- heavy-duty

- Other characteristics

- high-performance, high-productivity, high-rigidity, high-power

- X travel

1,020 mm

(40.16 in)- Y travel

550 mm

(21.65 in)- Z travel

530 mm

(20.87 in)- Rotational speed

8,000 rpm, 12,000 rpm

(50,265 rad.min-1, 75,398 rad.min-1)- Power

15 kW, 15.6 kW, 18.5 kW, 30 kW

(20.39 hp, 21.21 hp, 25.15 hp, 40.79 hp)- Work feed X-axis

30,000 mm/min

(20 in/s)- Work feed Y-axis

30,000 mm/min

(20 in/s)- Work feed Z-axis

24,000 mm/min

(16 in/s)- Table load capacity

1,000 kg

(2,205 lb)- Weight

7,000 kg

(15,432.36 lb)- Overall length

2,467 mm

(97.1 in)- Overall width

3,350 mm

(131.9 in)- Overall height

2,800 mm, 3,015 mm

(110.2 in, 118.7 in)

Description

Mynx II vertical machining centers are big, powerful and versatile.

They are the number one choice for heavy-duty milling operations.

Mynx machines can be supplied with different spindle configurations to meet you r needs and requirements.

Highlight

Excellent Machining Capability

Faster Machining

Stability

Different size and different capacity Mynx machines are available to meet individual customer's’ requirements.

A comprehensive machine line-up with Y-axis capacity ranging from - 550mm (21.7inch) to 950mm (37.4 inch), plus spindle options for machining different materials and workpieces.

High productivity and stable precision plus powerful cutting performance

Highly-rigid structure provides high durability and accuracy for heavy duty cutting.

Higher productivity can be achieved with the CAM-type tool changer that enables faster tool changes

Easy operation of the NC system

Quick and easy operation of the control system improves productivity.

The user-friendly EOP facility speeds-up and improves job set-ups, programming, trouble-shooting etc.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Doosan Infracore Machine Tools‘s catalogsOther Doosan Infracore Machine Tools products

Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-precision turning center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- High-performance turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.