- Machine-tools

- Machining Center

- 3-axis machining center

- Doosan Infracore Machine Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

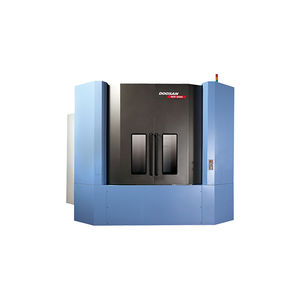

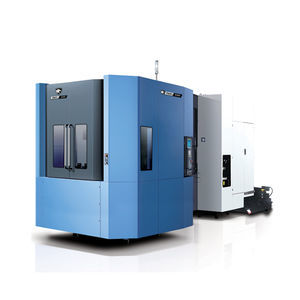

3-axis CNC machining center DNM 4000verticalhigh-productivityhigh-precision

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Other characteristics

- high-productivity, high-precision

- X travel

520 mm

(20.47 in)- Y travel

400 mm

(15.75 in)- Z travel

480 mm

(18.9 in)- Rotational speed

12,000 rpm

(75,398 rad.min-1)- Power

11 kW, 18.5 kW

(14.96 hp, 25.15 hp)- Work feed X-axis

48,000 mm/min

(31 in/s)- Work feed Y-axis

48,000 mm/min

(31 in/s)- Work feed Z-axis

48,000 mm/min

(31 in/s)- Table load capacity

400 kg

(882 lb)- Weight

3,300 kg

(7,275.25 lb)- Overall length

2,858 mm

(112.5 in)- Overall width

2,753 mm

(108.4 in)- Overall height

2,753 mm

(108.4 in)

Description

With a global installed base in excess of 30000 machines, the DNM series is a popular and proven mainstay in DN SOLUTIONS’s product line. With a range of different models, sizes and capacities - there is definitely a DNM machine that meets your needs.

Highlight

Reliability

Excellent Machining Capability

Stability

The largest machining area in its class.

New DNM series machines are equipped with a larger table with increased Y-axis travel and higher table load.

Direct-coupled spindle for higher productivity

Improves the machines’ performance and their environmental-friendliness, compared to belt driven types.

Higher productivity is achieved by reducing the tool change time and improving all axes feed rates plus acceleration/deceleration times.

An environmentally-friendly machine designed for stable and easy operation

The EOP function can be accessed via the pop-up window on the NC main screen

Grease lubrication for axis roller guideways supplied as standard

Catalogs

No catalogs are available for this product.

See all of Doosan Infracore Machine Tools‘s catalogsOther Doosan Infracore Machine Tools products

Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.