- Industrial machines and equipment

- Mixing and Dosing

- Adhesive batch blender

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

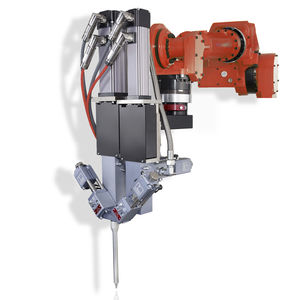

Adhesive mixing and metering unit volumixwith piston pumpfor the aerospace industrytwo-component

Add to favorites

Compare this product

Characteristics

- Product

- adhesive

- Type

- with piston pump

- Applications

- for the aerospace industry

- Other characteristics

- two-component

Description

Efficient cartridge filling with 2K polysulfide materials

Aircraft wings have to withstand the greatest stresses. The highest requirements therefore apply when bonding and sealing with 2K polysulfide materials.

In aircraft construction, a wide range of different adhesives and sealants are processed, each of which must be precisely metered and mixed. This ensures that the total weight of the aircraft is kept as low as possible.

The metal components are bonded and sealed with the utmost precision - mainly manually. Cartridges are used for this purpose, which are filled with two-component polysulfide-based materials at special metering and mixing stations.

In addition to easy handling, the volumix therefore offers a fully inline controlled, precise volumetric metering and mixing process.

Precision and reliability at every level

• The volumix is specifically designed to handle polysulfide materials used in the aircraft industry for bonding and sealing applications.

• The volumix is designed to automatically perform the filling process of cartridges and other small containers of mixed polysulfide material.

• All dispensing operations are continuously monitored by inline flow metering systems. This ensures that the specified mixing ratio is maintained at all times. The control takes place via a Siemens control system.

Catalogs

Volumix

4 Pages

Other DOPAG - Metering, Mixing and Dispensing Technology products

2K Metering Systems - Piston Metering Systems

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Chemical pump

- Industrial robot

- Lubricant pump

- Metering pump

- Manual gun

- Floor-mounted robot

- Volumetric dosing unit

- Liquids dosing unit

- Gear pump

- Vane pump

- Spray gun

- Medium-viscosity product pump

- DOPAG batch blender

- Abrasive fluid pump

- Modular pump

- Cartesian robot

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.