- Hydraulics - Pneumatics

- Valve

- Chemical product pressure regulator

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

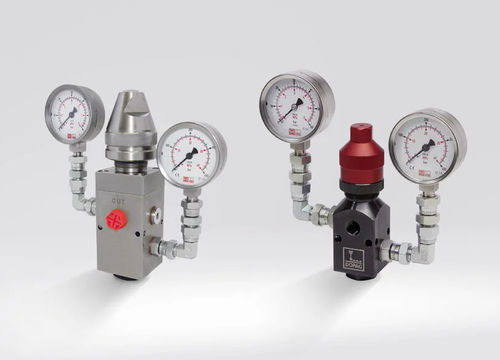

Chemical product pressure regulator lubriLinediaphragmpistonsingle-stage

Add to favorites

Compare this product

Characteristics

- Product

- for chemical products

- Technology

- diaphragm, piston

- Number of stages

- single-stage

- Applications

- industrial

- Other characteristics

- high-precision, for viscous fluids

- Pressure

Min.: 20 bar

(290.08 psi)Max.: 400 bar

(5,801.51 psi)- Flow

Min.: 0.07 l/min

(0.02 us gal/min)Max.: 15 l/min

(3.96 us gal/min)- Orifice diameter

Min.: 4.8 mm

(0.189 in)Max.: 12 mm

(0.472 in)

Description

DOPAG material pressure regulators reduce the pressure of the pumped material down to the optimum working value. They are designed specifi cally for the precise dosing of greases, oils and silicones. Along with reducing pressure, the valves also compensate for pulsations that occur when material is delivered via piston pumps, more specifi cally in the moment of the changeover position of the pump. This problem manifests itself in fluctuations in material pressure and fl ow, and can lead to reduced product quality - particularly in cases of very small doses, continuous or spray applications. The material pressure regulator is a guarantee of a perfectly stable material flow. For abrasive or reactive material, we recommend our material pressure regulator with a diaphragm.

• MPR with piston

This type of material pressure regulator is especially suitable for the processing of selflubricating materials such as greases and oils as well as single and plural component silicones. The sealing of the spring space takes place via a slide ring seal.

• MPR with diaphragm

This type of material pressure regulator is most suitable for use with reactive, moisture sensitive and, because the ball and seat are manufactured from tungsten carbide, also abrasive media, such as, epoxy resins, polyurethanes and many other materials. The sealing of the spring space takes place via the diaphragm.

Catalogs

Other DOPAG - Metering, Mixing and Dispensing Technology products

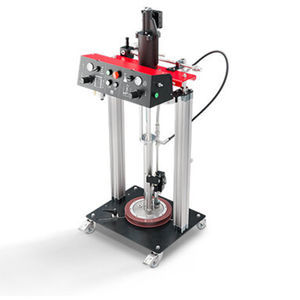

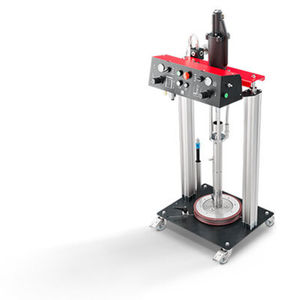

Drum Pumps

Related Searches

- Valve

- Hand valve

- Control valve

- Pneumatic valve

- Valve with flange

- Electric valve

- Pneumatically-operated valve

- Pressure limiter

- Single-stage regulator

- Oil valve

- Industrial regulator

- Radial diaphragm valve

- Compact valve

- Diaphragm pressure regulator

- Small valve

- Needle valve

- Aluminium valve

- Automatic valve

- Adjustment valve

- Piston regulator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.