- Hydraulics - Pneumatics

- Pump

- Electric grease pump

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

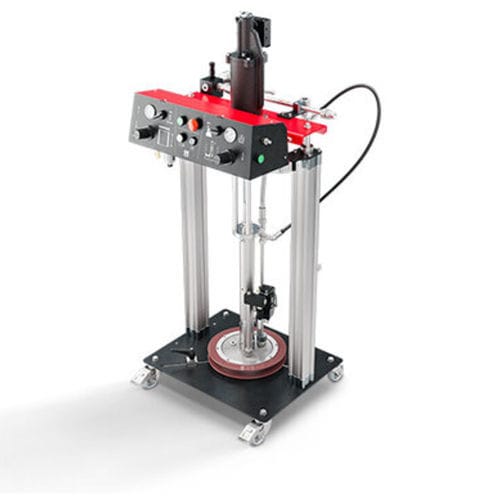

Electric grease pump P-LL Seriesfollower plate

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Technology

- follower plate

Description

The drum pumps of the lubriLine product range have been specially developed for the efficient processing of lubricants in consistency classes NLGI 0 to 4. Their robustness ensures a long service life and smooth operation. Users also benefit from a high ease of maintenance.

Benefits for you

• Individual configuration

• User-friendly and ergonomic 2-hand operation

• Material circulation and homogenisation prevent material separation

• Drum bottom detection to minimise material loss when changing containers

• Automatic follower plate deairing to make changing containers easier

• Clean, oil-free high-performance drives

Individually configurable

The modular design enables individually configured pumps for every requirement. Depending on customer requirements, the drum and barrel pump can be expanded with various options such as mixers, filters or an external communication for monitoring and control purposes.

Ensuring high-quality processing

In order to reduce the system pressure during downtimes and prevent material separation, a pressure release or homogenisation unit can be optionally integrated. When the pressure is relieved, it is ensured that the pump and ram pressure are relieved. In the homogenisation unit, the material is additionally circulated by being transported through a mixer and from there back into the container by a circulation circuit.

Reducing waste

To reduce material waste when changing containers, it is also possible to use drum bottom detecion. This is fitted on the follower plate and ensures that the container is emptied to a minimum residual amount.

VIDEO

Catalogs

No catalogs are available for this product.

See all of DOPAG - Metering, Mixing and Dispensing Technology‘s catalogsOther DOPAG - Metering, Mixing and Dispensing Technology products

Drum Pumps

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.