Modular solutions for electronic components and for the mobility of the future

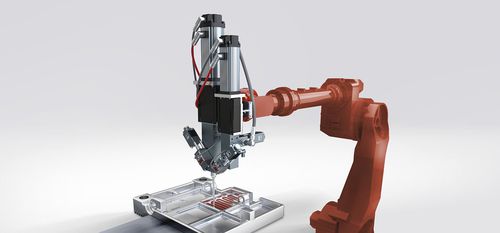

The vectomix TC was developed especially for metering, mixing and applying thermally conductive materials. They are used when heat must be spread and carried away consistently – for example in batteries or electronic components. Thermally conductive materials contain a high proportion of abrasive fillers. For this reason the vectomix TC is made of hardened steel to minimize abrasion.

It consists of two piston metering units which are available in different sizes and which can be combined together. This modular structure enables a diverse range of applications as well as variable mixing ratios and discharge ratios.

This system is also known for its efficient servo control. Both metering units have their own independent drive. This enables them to be controlled separately, which means that the mixing ratio can be adjusted and controlled precisely. The discharge rate can also be modified by means of an analogue signal during metering, such as to ensure a clean coupling point via a ramp function.

With integrated actuators and sensors, and supported by intelligent software, the vectomix TC metering system offer exceptionally high process reliability. The material is supplied by a drum pump, which is available in different sizes and as tandem version.