- Packing - Handling - Logistics

- Packing and Packaging

- Automatic filling machine

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

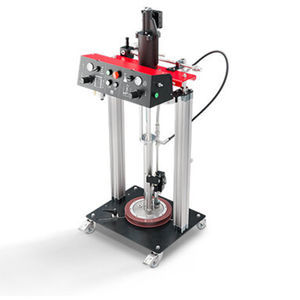

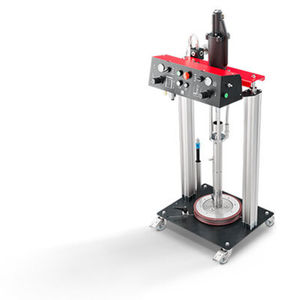

Automatic filling system glueLinecontainerlubricating oiltank

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- container

- Product applications

- lubricating oil, for adhesive materials, tank

- Number of heads

- with 2 heads, with 1 head

- Other characteristics

- compact, fill-to-level

- Volume

20 l, 30 l, 200 l, 1,000 l

(1 gal, 5.3 gal, 52.8 gal, 264.2 gal)

Description

To ensure uninterrupted production, automated refilling of the material pressure tanks is essential. DOPAG offers various compact refill units for this purpose. The fill level probe in the material pressure tanks enables refilling to be started automatically from a defined material quantity. This ensures that there is always sufficient conditioned material available for production and machine downtime is avoided.

Depending on the material type, the following refill units are available:

• If the material needs to be stirred cyclically, this can be performed using an agitator and cyclic operation. Homogenisation during drum change is also possible.

• For more fluid systems, in particular, isocyanate, DOPAG offers refilling via a membrane pump.

• Silica gel air drying for use with media sensitive to atmospheric moisture

• Depending on material consumption, 200 L drums or 20/30 L containers can be selected. Refilling from 1,000 L containers is also possible. In the case of non-self-levelling materials, DOPAG offers a wide range of drum and barrel pumps.

• Dual refill units are optionally available for quick, convenient drum changes. Here, two material drums are positioned side by side on the collection tray, and the drums are replaced by swivelling the bell housing.

Catalogs

glueLine

23 Pages

Drum pumps

12 Pages

Other DOPAG - Metering, Mixing and Dispensing Technology products

Drum Pumps

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.