- Industrial machines and equipment

- Mixing and Dosing

- Liquids batch blender

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

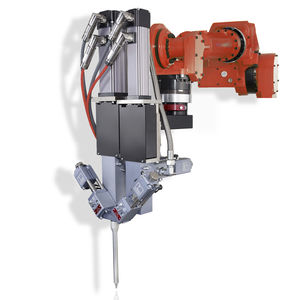

Piston mixer-dispenser silcomixfor medium-viscosity mediasiliconefor injection molding machines

Add to favorites

Compare this product

Characteristics

- Product

- silicone, for medium-viscosity media

- Type

- piston

- Applications

- for injection molding machines

- Other characteristics

- multi-component, high-precision, continuous, compact

Description

Extremely precise and efficient dosing of LSR in injection moulding processes

The silcomix is a compact-designed, electrically driven piston pump metering and mixing system. It is used for continuous processing of medium to high-viscosity silicone-based media with a mixing ratio of 100:100. Metering is carried out directly from the original containers with a size of 20 or 200 l.

Features and benefits

• High energy efficiency through servo-electrically driven piston pumps

• Extremely low material waste through simultaneous drum drainage and use of special supply pumps (material residual quantity in drum < 1 %)

• User-friendly system operation thanks to 7” touch panel

• Precise adherence to mixing ratio through synchronous switching of piston pumps (SWIPSYNC)

• Compact, space-saving system design

• Compatible with pallet trucks and forklifts

• Extremely good control behavior; even small shot sizes are possible in optimal quality

• Flexible operation thanks to processing from 20 or 200l containers (on a chassis)

• Process reliability thanks to data monitoring and archiving

• Processing of abrasive media for pigment metering through special sealing technology

Catalogs

LSR silcomix

12 Pages

Other DOPAG - Metering, Mixing and Dispensing Technology products

2K Metering Systems - Piston Metering Systems

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Chemical pump

- Industrial robot

- Lubricant pump

- Metering pump

- Manual gun

- Floor-mounted robot

- Volumetric dosing unit

- Liquids dosing unit

- Gear pump

- Vane pump

- Spray gun

- Medium-viscosity product pump

- DOPAG batch blender

- Abrasive fluid pump

- Modular pump

- Cartesian robot

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.