- Industrial machines and equipment

- Mixing and Dosing

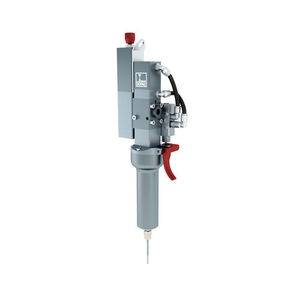

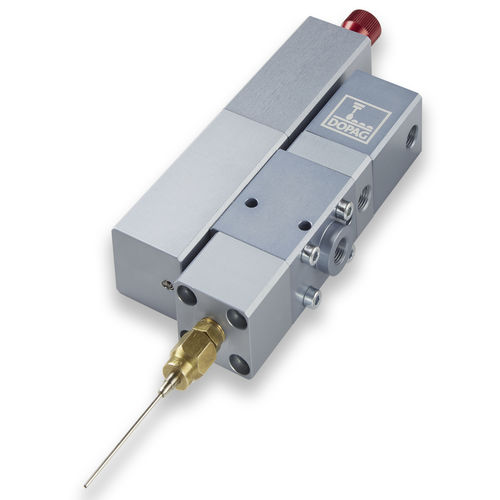

- Volumetric dispensing valve

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Volumetric dispensing valve lubriLineprecisionlubricant

Add to favorites

Compare this product

Characteristics

- Type

- volumetric

- Other characteristics

- precision

- Products

- lubricant

Description

Precise metering of lubricants

Chamber metering valves offer one of the most accurate ways of metering. They work according to the volumetric metering principle and process lubricants with high precision – without the need for additional monitoring and with little maintenance.

Benefits for you

• Up to 8 million shots with consistent accuracy thanks to the DOPAG Long Life Seal Concept

• Metering accuracy < ±1 percent

• Short cycle times

• Reliable process even without additional monitoring

• Clean break, absolutely uniform dot application

Work with repeat accuracy

Chamber metering valves work according to the volumetric metering principle. The material is discharged in shots via a metering piston. This results in a metering process that is insensitive to pressure fluctuations (25 – 150 bar). Benefit from maximum repeatability, reproducibility and process reliability.

The metering volume (0.05 to 100 ml) can be infinitely adjusted and fixed quickly and easily using a stop screw. The same valve can therefore be used for different metering quantities and end products.

Save time and money with our technology

With the DOPAG Long Life Seal concept, we have further improved the sealing technology of the series, which has been tried and tested over many years. Intensive field tests have shown that the valve applies approximately 1.2 million shots without leakage. Up to 8 million shots can be metered with consistent accuracy.

VIDEO

Catalogs

Other DOPAG - Metering, Mixing and Dispensing Technology products

Metering Valves

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Chemical pump

- Industrial robot

- Lubricant pump

- Metering pump

- Manual gun

- Floor-mounted robot

- Volumetric dosing unit

- Liquids dosing unit

- Gear pump

- Vane pump

- Spray gun

- Medium-viscosity product pump

- DOPAG batch blender

- Abrasive fluid pump

- Modular pump

- Cartesian robot

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.