- Industrial machines and equipment

- Welding and Assembly

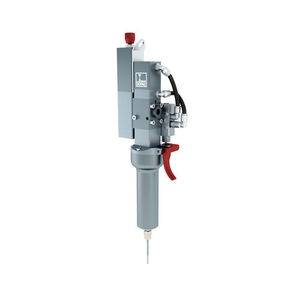

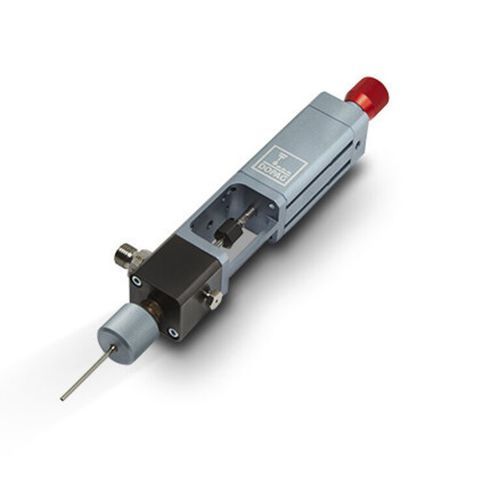

- Needle dispensing valve

- DOPAG - Metering, Mixing and Dispensing Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Needle dispensing valve lubriLineprecisionhigh-speedfor adhesives

Add to favorites

Compare this product

Characteristics

- Type

- needle

- Other characteristics

- precision, high-speed

- Products

- for adhesives, for oil, for sealants

Description

Quick and precise metering of small quantities

The needle metering valve is an all-rounder: It processes very small amounts of greases, oils, adhesives and sealants with high precision. And in no time at all. You also benefit from low maintenance costs and reliable production.

Benefits for you

• Unique minimal quantity valve with a minimum metering volume of 0.001 ml

• Up to 10 million shots leak-free thanks to the DOPAG Long Life Seal concept

• Metering accuracy < ±1 per cent

• Short cycle times with up to 2 shots per second

For stable production processes

The needle metering valve works according to the volumetric metering principle, application is carried out in shots. The metering quantity is fixed by means of a stop screw. This ensures extremely high repeatability, reproducibility and process reliability at all times. The same valve can be used for different metering quantities and end products.

Fast cycle times

The needle metering valve is insensitive to pressure fluctuations (3–50 bar) and thus also independent of viscosity and temperature changes. A system temperature control device is not necessary. Pressure tanks can be used to process low-viscosity materials. The material is ejected directly from the needle metering valve. This is why extremely short cycle times are possible.

Reliable production processes

With the DOPAG Long Life Seal concept, up to 10 million shots are possible leak-free. Compared to existing variants, this results in 20 per cent lower maintenance costs and fewer interruptions to your production process.

VIDEO

Catalogs

Other DOPAG - Metering, Mixing and Dispensing Technology products

Metering Valves

Related Searches

- DOPAG dispensing valve

- Precision dispensing valve

- Applicator

- Grease dispensing valve

- Needle dispensing valve

- Viscous product dispensing valve

- Adhesive dispensing valve

- Diaphragm dispensing valve

- Lubricant dispensing valve

- DOPAG oil dispensing valve

- High-speed dispensing valve

- Aggressive liquid dispensing valve

- Sealant dispensing valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.