- Power Transmission - Mechanical components

- Actuator and Positioning System

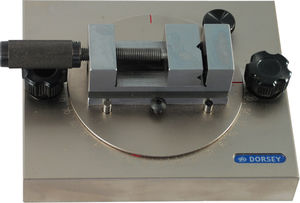

- XY positioning stage

- Dorsey Metrology International

Linear positioning stage XYmotorized2-axis

Add to favorites

Compare this product

Characteristics

- Orientation

- linear, XY

- Type

- motorized

- Number of axes

- 2-axis

Description

These coordinate stages can be used for optical comparators, vision systems or microscopes. Dorsey offers fully motorized or manual comparator stages. These stages allow adjusting the position of inspected part. Inspected elements mounted on stage are resistant to external vibration providing more accurate results.

Features:

High precision solid rail crossed roller bearings

Hard nickel plated surfaces

Fixturing holes with universal spacing

Quick release on both axes of all manual stages

Static axis bias on stage drives increases accuracy

Universal mounting options fit many existing systems

Choice of scale resolutions

Motorized versions available with stepper or servo motors

Motorized versions available with slip clutches or limit switches

Accuracy formula +/- .004 +[(L/20).001]

NIST traceable calibration certificate

2 Year Warranty

Catalogs

No catalogs are available for this product.

See all of Dorsey Metrology International‘s catalogsOther Dorsey Metrology International products

Optical Comparators

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.