- Building - Construction

- Construction and Mining Equipment

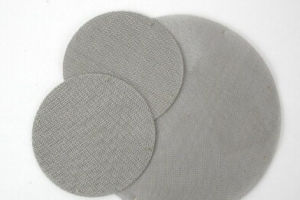

- Screening grate

- Dorstener Drahtwerke

Screening grate stainless steelsteel

Add to favorites

Compare this product

Characteristics

- Options

- screening

- Material

- stainless steel, steel

Description

We weave screen cloth as a square weave according to ISO 9044 and ISO 4783. We store a broad range of square weave variants with a width of up to 3,000 mm in our warehouse with a separation size between 20 μm – 30 mm. Oblong and broad opening meshes offer a larger open area and a reduced tendency to clogging.

Nowadays, the most often used stainless steel materials are 1.4301, 1.4401 and 1.4016.

Upon request, we manufacture duplex materials and other grades of stainless steel. High-tensile stainless steel grades (e.g. 1.4310) and spring steel cloth (DIN EN 10270) offer higher abrasion resistance and improved vibration behavior.

Screens for heavy-weight materials are normally manufactured from pre-crimped woven wire meshes in spring steel (DIN EN 10270) or stainless steel 1.4301 or 1.4401 and equipped with hooks.

The opening type and type of weave is determined by the application and can either be in a square, rectangular or longish shape. The rule of thumb applies: The more longish the weave, the more yield, less tendency to cluster or clog but also less precise the sieve will be. Those meshes offer separation sizes between 1.0 – 100 mm.

Harp screens are a special form of wire screens. They are particularly suitable for difficult, regularly moist and loamy sifting materials. They provide a high throughput and a good self-cleaning efficiency. Harp screens are mainly made from stainless steel.

Hooks are the most widespread method for mounting screens onto vibratory screeners. They are designed depending on the mesh and the type of screening machine.

Screens as longitudinal or transverse tensioners with tensioning folds are available with all common fold types.

Catalogs

No catalogs are available for this product.

See all of Dorstener Drahtwerke‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.