- Products

- Dropsa spa

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

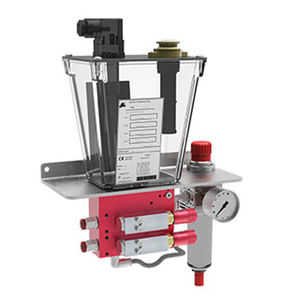

Bearing divider 11327 series for proportional valveairoil

Add to favorites

Compare this product

Characteristics

- Product applications

- air, for bearings, for proportional valve, oil

Description

This Air/Oil lubrication splitter block is a proportional divider that approximately divides an air/oil mixture stream into equal proportion according to the number of outlets.

An Air/Oil mixture is fed into the inlet and the splitter divides the mixture into two, four, six or eight outlets.

Dropsa has optimized the division of the air/oil stream by use of extensive CFD and practical experimentation data to optimize output deliver. This allows a more precise delivery of air/oil flow to the lubrication points than conventional splitter blocks.

The Air/Oil Lubrication splitters are used generally for lubrication of bearings in rolling mills and levelling machines.

The main advantage of using air/oil splitter block technology is given by the requirement for only a single tubing containing the Air –Oil flow. There is no requirement for dual tubing (one for air one for oil) up to the lubricating device as is common on volumetric system.

Splitter Block technology is less accurate than volumetric technology but can achieve substantial saving on initial system costs due to the reduction in tubing.

Key features:

- Material: Brass

- Working temperature: -5 °C ÷ +70 °C

- Oil lubricants: 32÷460cSt

Catalogs

No catalogs are available for this product.

See all of Dropsa spa‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.