- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

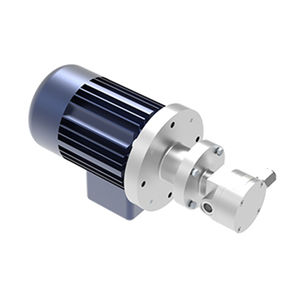

Motorized lubrication system Dragonoilgreasecentralized

Add to favorites

Compare this product

Characteristics

- Lubricant

- oil, grease

- Type

- centralized

- Applications

- for machine tools, chain, for presses

- Power source

- electric

- Other characteristics

- automatic, compact, motorized

Description

The Dragon series pumps, being extremely compact and versatile, is particularly suitable for lubricating presses, reducers, machine tools, guides and chains. The gear pump interlocks the lubrication circuit and is available in two versions: the first has a flow rate of 350 cm³/min (21.3 cu.in/min), the second has a flow rate of 500 cm³/min (30.5 cu.in/min), both operating at 1500 rpm. The Dragon pump can be customized according to the different needs of the user thanks to a wide range of electric motors and tanks available. It is also possible to equip the Dragon pump with an Integrated Control Panel (entitled VIP Controller, which allows the transmission of programs using infra-red rays) or with a Manual Control device which has to be connected to a separate electronic equipment.

Three basic versions available: for lubrication systems with injectors and for recirculation systems with operating pressure < 20 bar (<290 psi) system 01. With a built-in release valve, for lubrication systems equipped with "direct response" feeding devices with operating pressure < 70 bar (<1015 psi) system 33V. For progressive lubrication systems and for circulation systems controlled by progressive feeding devices with operating pressure <70 bar (<1015 psi) system 26.

Maximum Pressure: at intermittent running is 70 bar (1029 psi) with a three-phase motor and 40 bar (588 psi) with a single-phase motor under operating temperature between +5 ÷ +40 °C (41 ÷ 104 °F) and max. working timeof 5 minutes with 1:1 pause ratio. At continuous running is 30 bar for both single-phase and three-phase motor under operating temperature between +5°÷ +40°.

Related Searches

- Dropsa pump

- Dropsa industrial pump

- Dropsa valve

- Dropsa electric pump

- Dropsa stationary pump

- Fitting

- Dropsa self-priming pump

- Chemical pump

- Control valve

- Hydraulic fitting

- Stainless steel valve

- Pneumatic valve

- Metal fitting

- Dropsa lubricant pump

- Quick coupling

- Dropsa oil pump

- Compact pump

- Submersible pump

- Nickel-plated brass fitting

- Angle fitting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.