- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

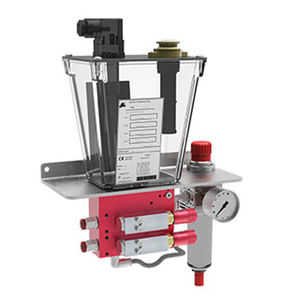

Air/oil lubrication system VIP4continuousfor machine toolselectric

Add to favorites

Compare this product

Characteristics

- Lubricant

- air/oil

- Type

- continuous

- Applications

- for machine tools

- Power source

- electric

Description

The lubrication system VIP4Air /Continuous Air has been designed to guarantee high performance at low price and is characterised by compactness. It has been conceived for use on:

- spindles;

- machine tool;

The panel is composed of a central unit which manages the entire system regulating and controlling the operation of the dividing and mixing modules, which are made up of pneumatically controlled mini-pumps and the mixing bases.

Mini-pumps can be arranged with different spacers in order to vary the flow rate and satisfy any requirement.

A flow control is integrated inside the mixing base, which is used by the central unit to verify the correct functioning of the equipment.

Modularity makes the system extremely versatile: up to 8 mixing bases can be mounted on each unit.

The high technology allows a total control of the lubrication while the simplicity of installation makes unnecessary the use of movable connections.

Key features:

- Power supply voltage 24 VDC - 110 VAC

- Electrical input 10 W

- Air supply pressure 5 - 8 bar (73.5÷117.6 PSI)

- Lubricant Synthetic mineral Oil

- Oil viscosity (at working temperature) 32÷220cSt (149.9÷1018 SUS)

- Output signal Remote alarm contact: max. 250 V 1 A NO/NC

- Working temperature +5 ÷ +55 °C (+41÷+131°F)

- Working humidity 90% max.

- Protection class IP-44

- Storage temperature -20÷+65 °C (-4÷+149°F)

Catalogs

Related Searches

- Dropsa pump

- Dropsa valve

- Dropsa industrial pump

- Dropsa electric pump

- Dropsa stationary pump

- Fitting

- Dropsa self-priming pump

- Chemical pump

- Control valve

- Hydraulic fitting

- Stainless steel valve

- Pneumatic valve

- Metal fitting

- Dropsa lubricant pump

- Quick coupling

- Compact pump

- Dropsa oil pump

- Submersible pump

- Nickel-plated brass fitting

- Angle fitting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.