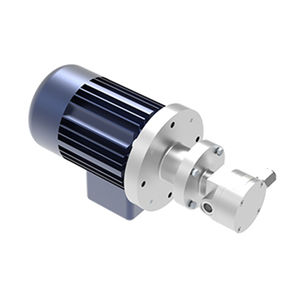

Single-point lubricator K001 series electrochemicalfor bearingsautomatic

Add to favorites

Compare this product

Characteristics

- Type

- single-point

- Technology

- electrochemical

- Applications

- for bearings

- Other characteristics

- automatic

- Capacity

120 cm³

(4 US fl oz)- Pressure

5 bar

(72.5 psi)

Description

The MONO point automatic lubricator is the most cost-effective solution alternative to manual lubrication.

It ensures that the correct lubricant is being used in the correct quantity, in the correct place at the correct time, reducing costly downtime and failures.

MONO contains its own unique chemical expulsion unit, that has no springs or mechanisms but relies on an unvarying law of nature.

It is activated by simply turning the activation cap – no separate activator is required.

The contained gas generator builds up a pressure of max. 5 bar, which moves the piston forward and transports lubricant into the lubrication point.

BENEFITS

- No further need for costly time consuming manual lubrication

- Labour saving/less labour intensive maintenance

- Improved health and safety

- Reduction in lubricant consumption

- Lessen environment impact

APPLICATIONS

MONO point lubricator reliably provides a continuous, controlled supply of grease to the bearings, gears and another wear components, keeping contaminants out and lubricant in. It is suitable for use in any industry or environment.

Key features:

- Housing design: Plastic Body and Thread

- Operating temperatures: from -20°C to 60°C (from -4°F to 140°F)

- Discharge period: 1, 2, 3, 4, 6, 8, or 12 months

- Compatible lubricants: Greases (to NLGI 2)

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Dropsa pump

- Dropsa valve

- Dropsa industrial pump

- Dropsa electric pump

- Dropsa stationary pump

- Fitting

- Dropsa self-priming pump

- Chemical pump

- Control valve

- Hydraulic oil fitting

- Stainless steel valve

- Pneumatic valve

- Metal fitting

- Dropsa lubricant pump

- Quick coupling

- Submersible pump

- Compact pump

- Dropsa oil pump

- Nickel-plated brass fitting

- Angle fitting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.