- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

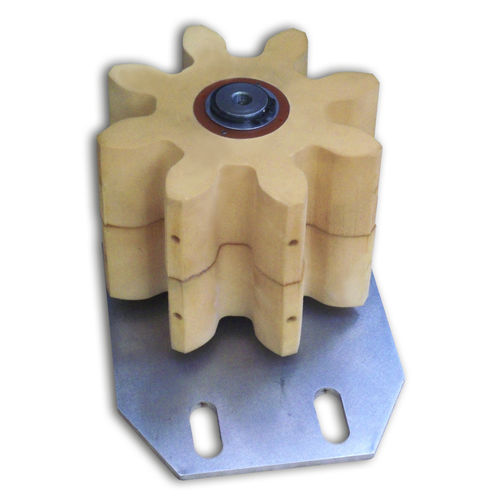

Straight-toothed sprocket wheel 03108 series steelstainless steel

Add to favorites

Compare this product

Characteristics

- Teeth

- straight-toothed

- Material

- steel, stainless steel

Description

The DropsA Lubrication pinion is an innovative solution that replaces manual and troublesome lubrication of gear rims and racks.

This solution saves time and money by allowing automatic application of precise quantities of lubricant.

The unit comprises a central rotary stainless steel axel centralized greasing distribution system and a absorbent foam allowing it to be used in demanding application due to its robustness.

Benefits of using Dropsa Lubrication Pinion over traditional methods.

- Grease is applied uniformly systematically and uniformly on all parts of the gear rim

- It is no longer left to the ability of the operator.

- The quantity of grease delivered can be accurately determined by the use of a Dropsa lubrication system.

- Use of a completely automatic lubrication system reduces operator costs to a minimum.

- Being completely automatic, the lubrication task is never forgotten!

The lubricating pinion rotates with the mobement of the rack, due to the rotation, the lubrificant is automatically deposited onto the rack, the, by meas of the central shaft supply, the sponge obtains new lubricatn from the pump unit.

Operating Principle

The lubricant is injected via the grease inlet port (A). This pressurizes the Stainless Steel rotary manifold (B). The rotary manifold arrangement interfaces with a number of radial holes (C) to bring the lubricant to the tip of the gear distributing it evenly over the pinion surface.

As the pinion is driven around by the gear rim the grease present on the Lubrication Pinion is applied in a uniform manner onto the gear rim.

Key features:

- Stainless steel Rotating Grease distribution manifold.

- Porous and absorbent foam.

Catalogs

No catalogs are available for this product.

See all of Dropsa spa‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.