- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

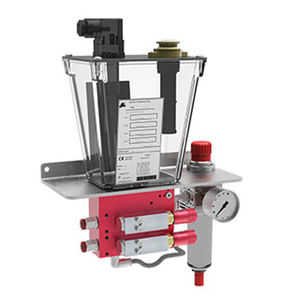

Air/oil lubrication system VIP4centralizedchaincontrollable

Add to favorites

Compare this product

Characteristics

- Lubricant

- air/oil

- Type

- centralized

- Applications

- chain

- Other characteristics

- automatic, compact, controllable

Description

Dropsa's new VIP4Chain Automatic Chain lubrication system is an advanced Chain or Conveyor lubrication system at a very affordable price

The Vip4chain has been designed to be used for Air/Oil Chain Lubrication, Spray or dispensing applications.

The automatic chain lubrication system is completly modular and very compact therefore can be quickly and easily installed following the instructions in this manual.

A sensor connected to the Vip4Chain's sensor-input monitors or 'counts' the chain movement; for example the number of links. The Vip4Chain can then be set to count how many links should be lubricated (from one to ten thousand) .

The unit consists of a base module which houses the electronic control and monitoring system. The unit can then be configured to have one or more (max. 6) dispensing modules which consist of an adjustable micropump (0-30 mm.³) fitted onto a modular mixing base element.

Inside the mixing base a flow control is integrated and it is used by the central unit to verify the proper functioning of the equipment.

Modularity makes the system extremely versatile, allowing you to install a variable number of bases of extensible mixing up to 6 elements.

The high technology included allows complete control of the lubrication, combined with ease of assembly that excludes unnecessary connections.

Key features:

- Operating Voltage: 24 Vdc 110 Vac

- Power Consumption: 10 W

- Air Input Pressure: 5 ÷ 8 bar

- Remote Alarm Signal: RELAY signal max 250 V 1 A N.O./N.C.

- Operating Temperature: -5 ÷ +55 °C

- Max. Working Humidity: 90% max

- IP Protection Grade: IP-44

- Compatible Lubricants: Mineral Oils

- Oil Viscosity: 32 ÷ 220 cSt

Catalogs

Related Searches

- Dropsa pump

- Dropsa valve

- Dropsa industrial pump

- Dropsa electric pump

- Dropsa stationary pump

- Fitting

- Dropsa self-priming pump

- Chemical pump

- Control valve

- Hydraulic fitting

- Stainless steel valve

- Pneumatic valve

- Metal fitting

- Dropsa lubricant pump

- Quick coupling

- Compact pump

- Dropsa oil pump

- Submersible pump

- Nickel-plated brass fitting

- Angle fitting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.