- Hydraulics - Pneumatics

- Pump

- Oil pump

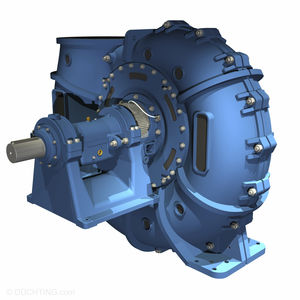

- DÜCHTING PUMPEN

Water pump MCoilelectricself-priming

Add to favorites

Compare this product

Characteristics

- Fluid

- water, oil

- Operation

- electric

- Priming

- self-priming

- Technology

- centrifugal

- Mobility

- stationary, mobile

- Domain

- industrial, for water treatment

- Applications

- discharge, service, reverse

- Material

- metal

- Fluid specification

- for corrosive fluids

- Other characteristics

- suction, single-stage, heavy-duty, mechanical, lubricated, flange, adjustable, vertical, seal

- Flow

Min.: 0 us gal/min

(0 l/min)Max.: 6,600 us gal/min

(24,983.71777 l/min)- Pressure

Min.: 0 psi

Max.: 150 psi

- Head

Min.: 0'00"

(0 m)Max.: 300'00"

(91.44 m)

Description

TYPE MC

Horizontal single-stage centrifugal pump in back pullout design.

Pumping of abrasive and corrosive liquids

All components which are in contact with the liquid are made of SICcast

Suction flange: Axial

Discharge flange: Top (Vertical)

Closed impeller with three-dimensionally curved vanes

Impeller is key driven; reverse rotation (e.g. back-flushing) is possible

Re-adjustable inclined gap between impeller and volute casing to optimize the efficiency and differential pressure after longer operation

Single acting, metal free mechanical seal DÜTEC with springs located outside of the liquid (other seal types available)

Oil-lubricated antifriction bearings

Back pullout design (the complete rotating assembly can be removed while the casing remains on its position)

In many applications the wear life of SICcast greatly exceeds convential materials

Available with heavy-duty bearing units for extreme applications

Optimized design ensures easy maintenance and long service life even under difficult conditions

Technical Data

Pump Size: - 1 1/4″ to 12″

max. Pressure: - 150 PSI

max. Flow: - 6600 gpm

Total head: - up to 300 ft

Rotating speed: - to 3600 rpm

Fields of Application

Pumping of abrasive and corrosive media

Flue gas desulfurization

Incinerators

Pigment industry

Chem. industry

Water treatment

Seawater desalination plants

Fertilizer industry / Potash industry

Materials

Spiral casing: SICcast

Impeller: SICcast

Shaft: 1.4462

Mechanical seal: Silicon carbide (SiC

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Suction pump

- Lubricating oil pump

- Submersible pump

- Mechanically-actuated pump

- Discharge pump

- Work pump

- Top-mounted pump

- Cast iron pump

- Vertical pump

- Slurry pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.