- Hydraulics - Pneumatics

- Pump

- Centrifugal pump

- DÜCHTING PUMPEN

Centrifugal pump MCVwaterelectricsubmersible

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- water

- Operation

- electric

- Priming

- submersible

- Mobility

- stationary, mobile

- Domain

- industrial, for water treatment

- Applications

- discharge, handling, work, cooling, treatment

- Material

- metal

- Other characteristics

- suction, mechanical, modular, flange, radial, large, vertical

- Flow

Max.: 55,000 us gal/min

(208,197.64812 l/min)Min.: 0 us gal/min

(0 l/min)- Pressure

Max.: 115 psi

Min.: 0 psi

- Head

Max.: 180'00"

(54.86 m)Min.: 0'00"

(0 m)

Description

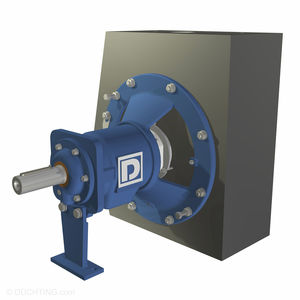

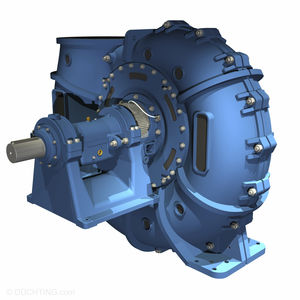

TYPE MCV

Single stage vertical centrifugal, sleeve-bearing pump.

Handling of abrasive and corrosive liquids

Vertical mixed flow pump designed for desalination plants to work as intake pump

Suitable for a wide flow range

Suction flange: Vertical

Discharge flange: radial

SICcast – inlet housing and diffuser withstand hard particles

Shaft sealing by a single acting mechanical seal

Polygon sleeve bearings support long shafts and protect against vibration. Radial bearings made of SiC on SiC

The modular design makes it possible to produce extremely large pumps at low costs

Easily disassambled wear plate

Optimized design to allow material choic

Technical Data

Pump Size: - 6″ to 40″

max. Pressure: - 115 PSI

max. Flow: - 55000 gpm

Total head: - up to 180 ft

Rotating speed: - to 1800 rpm

Fields of Application

Handling of abrasive and corrosive media.

Seawater intake

Water treatment plants

Cooling in power plants

Materials

All wetted parts (except shaft) are made of metal free materials to avoid corrosion totally.

Different shaft materials available according to the application requirements.

All hydraulic parts and the Discharge bend are manufactured in SICcast. Anti-corrosion lifetime guarantee for all SICcast parts in seawater applications.

Catalogs

MCV

12 Pages

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Suction pump

- Lubricating oil pump

- Submersible pump

- Mechanically-actuated pump

- Discharge pump

- Work pump

- Top-mounted pump

- Cast iron pump

- Vertical pump

- Slurry pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.