Saves Valuable Production Time

Soniseal™ WD bonders have full wash-down capability and can remain on the machine during cleaning. No bagging necessary!

Resists Corrosion

Strong, hermetic seals eliminate the need to bag the system when cleaning.

Designed to IP 67 Standards

Withstands high pressure chemical wash down and high temperatures.

Faster Processing Speed While Maintaining Seal Integrity

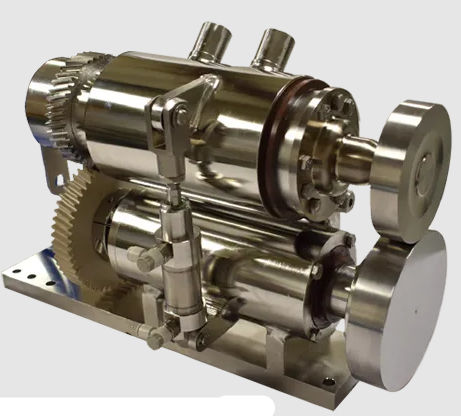

Focused energy and the “flywheel effect” of the rotary system allow for greatly increased sealing speeds and highly consistent seal integrity.

Integrates into Existing Machine Configurations

Soniseal™ bonders have a lightweight, compact design with a small machine footprint and is easily integrated into existing machine configurations.

Reduced Energy Costs when Compared to Heat Sealing

Reduced energy consumption and product damage are due to concentrated heat production during weld.

Offers Precise Control of Seal During Start-Stop Conditions

Rotary horns provide higher, continuous power delivery. More power means faster, more consistent sealing. Since the ultrasonic components do not need to “warm up”, start up and stop control of the machine is nearly instantaneous.