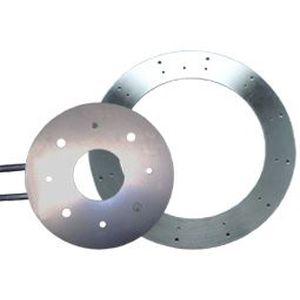

Custom heater high-temperaturecompact

Add to favorites

Compare this product

Characteristics

- Other characteristics

- custom, high-temperature, compact

- Temperature

1,000 °C

(1,832 °F)

Description

Durex Industries’ Rapid Fire aluminum nitride (AlN) ceramic heater solutions combine the thermal conductivity of aluminum and dielectric strength of specialty ceramics with physical properties similar to stainless steel. Additionally, a tungsten (W) RTD Sensor is integrated into the multi-layer heater construction to provide maximum control of this high watt density heater. New levels of machine design and thermal performance can be achieved through the excellent thermal, dielectric and physical properties of AlN heaters.

Ceramic heater technologies offer significant advantages over metal based sheath heaters that have limitations in thermal performance or material compatibility. Durex’ ceramic heaters can operate in atmospheric and vacuum environments up to 1000°C (1832°F). With its excellent thermal conductivity, AlN heaters can be designed with a multilayer construction that can deliver up to 2000 W/in2 (310 W/cm2 ). With chemical resistance to most acidic and alkaline solutions, these compact robust heaters are an ideal solution for demanding thermal applications. Ceramic heaters can be custom designed to optimize thermal performance for instrumentation and equipment applications.

Thermal conductivity equivalent to aluminum for fast and uniform thermal response

Watt density higher than any metal or ceramic heater technology for concentrated heat in a small area

Integrated RTD sensor for optimum heater temperature control

Dielectric strength eliminates need for magnesium oxide insulation (MgO) layer used in metal heaters

VIDEO

Catalogs

No catalogs are available for this product.

See all of Durex Industries‘s catalogsRelated Searches

- Resistance heater

- Tubular resistance heater

- Drum heater

- Flat resistance heater

- Flexible resistance heater

- Chiller-heater

- Stainless steel resistance heater

- Liquid chiller-heater

- Silicone resistance heater

- Aluminum resistance heater

- Custom resistance heater

- Belt drum heater

- Plastic drum drum heater

- Adhesive heating element

- Steel heating element

- Mica heating element

- Barrel drum heater

- Liquids and gase heating element

- Ring heating element

- Cast-in resistance heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.