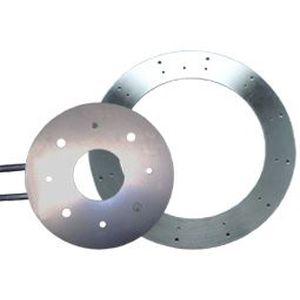

Cast-in resistance heater aluminum

Add to favorites

Compare this product

Characteristics

- Type

- cast-in

- Material

- aluminum

Description

Cast-in heaters are a unique heat source that can be adapted to many high-performance applications. Cast-in heaters are basically a heated part or tool that can be conceptualized and integrated as a component in a variety of equipment such as hot melt adhesives, foodservice, medical, packaging, paint spraying, semiconductor, and process pipelines.

The heating element is cast into aluminum, bronze, or iron and is an integral part of the final metal part, therefore operating at maximum heater efficiency, and eliminating the need to supply a heater as a second component attached to a machined component.

Durex engineering can assist with the process of specifying cast-in heated parts to fit your application. Additional components such as terminal boxes, threaded fittings, special tubing, or temperature sensors can be cast-in as system requirements dictate.

Catalogs

No catalogs are available for this product.

See all of Durex Industries‘s catalogsRelated Searches

- Resistance heater

- Heater

- Gas heater

- Electric heater

- Immersion heater

- Liquid heater

- Tubular resistance heater

- Circulation heater

- Drum heater

- Heating cable

- Flat resistance heater

- Stainless steel heater

- Flexible resistance heater

- Chiller-heater

- Stainless steel resistance heater

- Liquid chiller-heater

- Compact heater

- Silicone resistance heater

- Aluminum resistance heater

- Metal hot plate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.