- Production Machines

- Textile machinery

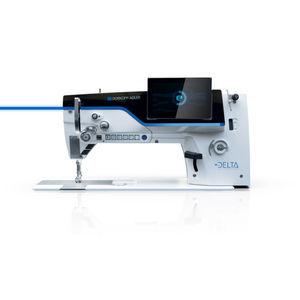

- Lockstitch sewing machine

- Dürkopp Adler AG

Cylinder arm sewing machine 550-869lockstitchtwin-needlesingle-thread

Add to favorites

Compare this product

Characteristics

- Stitch type

- lockstitch

- Number of needles

- twin-needle

- Number of wires

- single-thread

- Applications

- fabric

- Configuration

- fixed

- Control

- mechanical

- Drive type

- direct-drive

- Options and accessories

- automatic, with thread trimmer, cylinder arm

- Stitch length

9 mm

(0.354 in)

Description

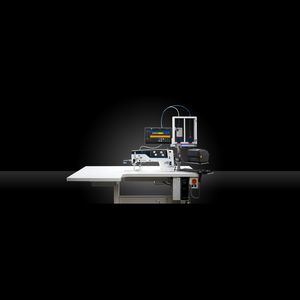

Due to the particularly large clearance of 1,000 mm under the sewing head and the step-motor driven rotating arm the M-TYPE cylinder arm machine guarantees maximum quality and efficiency processing tubular workpieces up to 10 meters long.

Automatic functions like pneumatic sewing foot lift, automatic backtacking, quick stroke adjustment, second integrated stitch length and pneumatic additional thread tension guarantees maximum ease of use.

The particulary large clearance of 1,000 mm under the sewing head enables the processing of very long hose materials

The extremely solid cylinder arm makes it possible to withstand high mechanical forces and loads

The small cylinder arm diameter allows the processing of tube filters with narrow diameter

Integrated direct drive with networkable DAC classic control incl. operating panel OP1000 – Industry 4.0 „ready”

The automatic thread trimmer reduces thread consump tion when processing very long tubular filters

Powerful feeding system combined with a stepper motor driven rotating arm

Equipped with electric height adjustable stand set

EXAMPLES OF USE

Sewing operations on tubular workpieces

Catalogs

No catalogs are available for this product.

See all of Dürkopp Adler AG‘s catalogsRelated Searches

- Fixed sewing machine

- Single-needle sewing machine

- Fabric sewing machine

- Automatic sewing machine

- Lockstitch sewing machine

- Single-thread sewing machine

- Sewing machine with thread trimmer

- Table sewing machine

- High-speed sewing machine

- Twin-needle sewing machine

- Direct-drive sewing machine

- Chain stitch sewing machine

- Electronic sewing machine

- Programmable sewing machine

- 2-thread sewing machine

- Pattern sewing machine

- Shoe sewing machine

- Bag sewing machine

- Jean sewing machine

- Heavy fabric sewing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.