- Packing - Handling - Logistics

- Conveying

- Automatic sorter

- Dutch Vision Systems

High-speed sorter DS 200automaticfor small partsfor parts

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- for small parts, for parts, surface inspection, measurement

- Other characteristics

- high-speed

- Throughput

600 p/min

Description

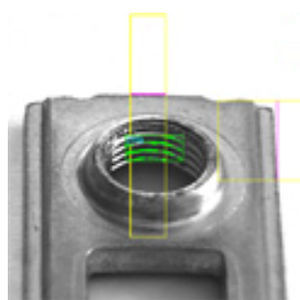

The diagonal sorter DS200 is designed both for surface inspections and for measuring large numbers of small cylindrical parts. However, other forms of geometry can also be tested.

The sorting machines are designed according to customer requirements with regard to infeed, test stations and ejection.

The ejection takes place in OK or NOK boxes with piece counting. The integration of a crate station or the connection to packaging machines are also possible.

Automatic tester system features:

•Up to 10 parts/s can be inspected automatically

•Surface inspection and/or measurement

•Quick conversion to similar products

•Controlled tracking of parts from infeed to ejection

•Level monitoring of all containers

•Automatic system analysis and self-explanatory visualization of the system status

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.