- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

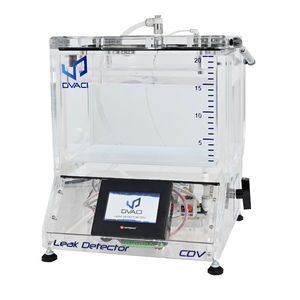

Leakage tester CDV FS SVVI

Add to favorites

Compare this product

Characteristics

- Test type

- leakage

Description

CDV FS SVVI will allow you to conduct the leak detection tests necessary to comply with sanitary and quality requirements of the food, cosmetic and or pharmaceutical industry.

They are equipped with a system controlled by a digital display that allows vacuum level to be set and two buttons that control start and stop of the test.

These models include a Venturi system that requires a compressed air supply available in the testing area in order to function. If an airline is not available, our electric vacuum pump models are the suited alternative.

They include their own base with wheels.

How does it work?

The test starts when user presses START button and the pressure regulator activates the vacuum generator until desired vacuum level is reached.

This level will be maintained automatically until user presses STOP button, and this is when vacuum is released.

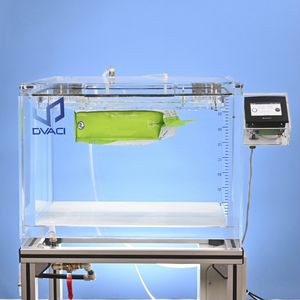

The user must observe the simple in the chamber during test. In immersion testing, bubbles will be sought seeping from any leak spot.

In a dry test, a leak may be detected when liquid spills or drops leak out of the sample.

ASTM D3078, ASTM D6653, ASTM D4991, ASTM D5094, ASTM D4169, ASTM F2096.

VIDEO

Catalogs

Related Searches

- Test cabinet

- Automatic test equipment

- Test chamber with window

- Industrial test equipment

- Portable test kit

- Battery test chamber

- Digital test kit

- Automatic test chamber

- Compact test chamber

- Tabletop testing device

- Test chamber for the pharmaceutical industry

- Laboratory test equipment

- Vertical test chamber

- Leak-proofing test chamber

- Compact test equipment

- Device test chamber

- Benchtop test cabinet

- Pressure test equipment

- Test kit for the automotive industry

- Leakage testing system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.