- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

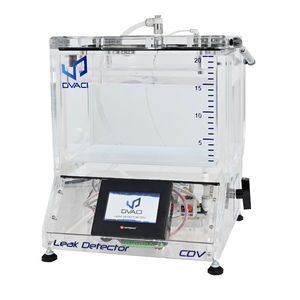

Glass frame vacuum chamber CDV VC

Add to favorites

Compare this product

Characteristics

- Other characteristics

- glass frame

Description

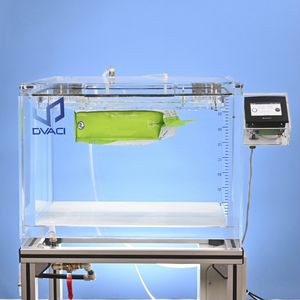

1- Package Leak Test | Seal Integrity Inspection Procedure

For non-liquid product packaging, we recommend performing leak testing in immersion to allow the observation bubble formation in holes or leakage in the seal.

For liquid product packages such as bottles or jars, we recommend to proceed with leak testing in a dry chamber. Liquid drops will appear from the leaking area.

In any case, packaging leak detection depends on operator’s visual observation.

2- Altitude Simulation Test Methods | Negative or Positive (optional) Atmospheric Pressure Variation.

3- Leak Test for Vacuum Packages

Optional – Includes additional kit that allows to inflate the product with a needle and foam seal pads – Bubble Detection Test

4- Packaging Burst Test. Determines Seal Opening Strength

5- Desiccator with our vacuum chamber CDV in a vertical version.

6- Conservation Storage Space – Free of Air and Oxygen

7- Scientific Experiment Usage

8- Industrial Applications: Laser in vacuum. Venting / Air extraction for silicone molds, etc.

Catalogs

No catalogs are available for this product.

See all of DVACI‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.