- Industrial machines and equipment

- Surface Treatment Equipment

- Solvent cleaning machine

- D.W. Renzmann Apparatebau

Solvent washing machine 360 sprayautomaticstainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- spray, solvent

- Operational mode

- automatic

- Other characteristics

- stainless steel

Description

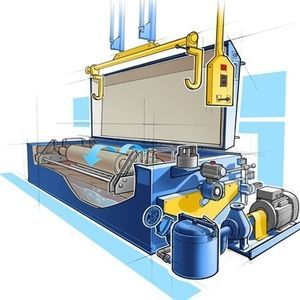

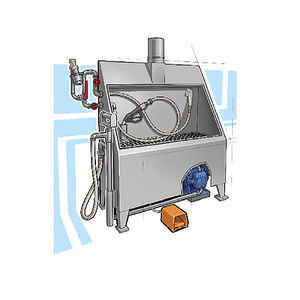

Machine to be loaded from the front with closed wash cabin and separate, machine-integrated wash solvent reservoir.

Pneumatically driven machine infeed, machine door is designed as machine front; operation of washing machine only possible if door is shut.

Machine infeed with powered rollers for the accommodation of the gravure cylinders. Adjustable rollers are powered by external ex-gear motor.

Stainless steel catch basins under machine infeed; prevents contamination of floor; moves synchronously to slide-in.

Individually designed wash and re-rinse spray system

Powerful wash pump / ex-motor power unit

Removable filter elements for the protection of spray system, pumps and piping.

Fill-level control for the integrated wash solvent reservoir (operation level, max. level)

Internal exhaust system with powerful ventilator and pneumatically controlled air-intake and air-admixture chokes

Automatic wash program (PLC), includes washing – drip off – re-rinse – internal exhaust. Individual program steps can be adjusted.

Equipment

Self-cleaning device

Solvent cooling, alternatively with thermostatic safety valve, water cooler or recooler

Workplace vapour extraction

Measuring and control system of solvent concentration for the connection to a waste-air purification system

Ideal machine design

Integration into existing rooms and cylinder logistics

Throughput washing machine with 2 doors

Itemization 360-W for aqueous alkaline cleaning

Other D.W. Renzmann Apparatebau products

Washing machines Graphic Industry

Related Searches

- Automatic washing machine

- Water washing machine

- Stainless steel washing machine

- Process washing machine

- Spray washing machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Compact washing machine

- Automotive washing machine

- Washing machine with rinsing

- Robust washing machine

- High-pressure washing machine

- Optical cleaning system

- Brush washing machine

- Washing machine with basket

- Compressed air washing machine

- ATEX washing machine

- Rotary washing machine

- Vertical washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.