- Industrial machines and equipment

- Surface Treatment Equipment

- Alkaline cleaning machine

- D.W. Renzmann Apparatebau

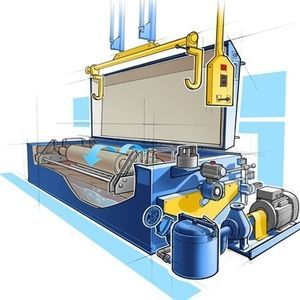

Alkaline washing machine HAsprayautomatichigh-pressure

Add to favorites

Compare this product

Characteristics

- Technology

- spray, alkaline

- Operational mode

- automatic

- Other characteristics

- stainless steel, high-pressure, top-loading

Description

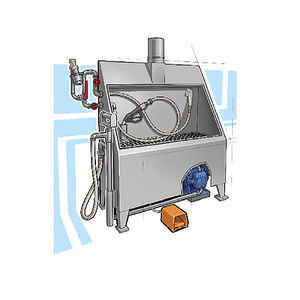

Top-loading machine with closed, stainless steel wash cabin

Machine made of stainless steel; operation of washing machine only possible if lid closed; opening only possible after completion of entire wash program.

Roll turning and bearing devices consist of two stainless steel axle shafts supported at the front side of the machine; powered by external gear motor.

No exact positioning in the machine required; lengths of wash items variable and no adjustments at the machine required.

Wash medium system for even spraying of contaminated wash item surfaces with alkaline medium.

Wash medium system consists of stainless steel wash medium container under wash chamber, circulation pump and a spray pump system.

Wash medium container equipped with instant water heater (temperature up to 60°C), fill-level control (operation level, max. level) and large, removable clarifying filter.

High-pressure system for directed spray wash of the wash item surfaces previously treated with the wash medium.

High-pressure system is equipped with high-pressure piston pump (pressure 100 bar) with connection

to customer‘s water network and horizontally oscillated carriage with high-pressure slot nozzle (travel adjustable).

Blower on horizontally moving carriage to remove any remaining water from wash item surfaces.

Control (PLC), including control elements and operating state lamps, located in timing case fitted to wash chamber. Automatic wash program includes: Spraying with wash medium – drip-off – high-pressure spray wash with longitudinal axis – blow-off with pressurized air; all operation processes take place while wash item is rotating.

Other D.W. Renzmann Apparatebau products

Washing machines Graphic Industry

Related Searches

- Automatic washing machine

- Water washing machine

- Stainless steel washing machine

- Process washing machine

- Spray washing machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Compact washing machine

- Automotive washing machine

- Washing machine with rinsing

- Robust washing machine

- High-pressure washing machine

- Optical cleaning system

- Brush washing machine

- Washing machine with basket

- Compressed air washing machine

- ATEX washing machine

- Rotary washing machine

- Vertical washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.