- Industrial machines and equipment

- Surface Treatment Equipment

- Solvent cleaning machine

- D.W. Renzmann Apparatebau

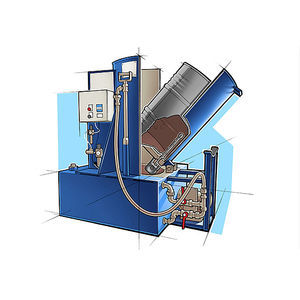

Solvent washing machine 6090rollerautomaticATEX

Add to favorites

Compare this product

Characteristics

- Technology

- solvent, roller

- Operational mode

- automatic

- Other characteristics

- robust, ATEX, brush

Description

Robust and user-friendly washing machine for inside and outside cleaning of barrels and small cylindrical containers with brushes and simultaneous spraying with solvent, conductive brushes with type examination according to ATEX → no nitrogen inerting required

Very good inside and outside cleaning with rotating roller brushes

Two separate spraying systems for washing with circulated solvent and rinsing with clean solvent

Tight closing, manual washing chamber door with counterweight

Position sensor for the door, spraying does not begin until the washing chamber is closed

Cylindrical washing chamber, tilted backward, very good draining of the solvent, no corners where residues can accumulate, hence low solvent emissions

Closed solvent tank under the washing chamber (no solvent vapors when the washing machine is open), level switch for filling and draining

Dirt resistant pneumatic double diaphragm pump as washing and evacuation pump, separate pump for rinsing

Strainer for protection of the solvent tank and the pump

Internal air extraction system with powerful suction fan

Flow monitor, start of brush rotation only after solvent has been sprayed on the containers; this is done to prevent dry friction caused by the brush rotation

Automatic washing program: washing – draining – rinsing – internal air extraction; program steps can be selected individually

Explosion protection according to ATEX, category 1 (with type examination) for zone 0 inside, category 2 for zone 1 outside

Accessories

Pneumatic ejection device for more convenient removal of barrels

Other D.W. Renzmann Apparatebau products

Washing machines Paint Producing Industry

Related Searches

- Automatic washing machine

- Water washing machine

- Stainless steel washing machine

- Process washing machine

- Spray washing machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Compact washing machine

- Automotive washing machine

- Washing machine with rinsing

- Robust washing machine

- High-pressure washing machine

- Optical cleaning system

- Brush washing machine

- Washing machine with basket

- Compressed air washing machine

- ATEX washing machine

- Rotary washing machine

- Vertical washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.