- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

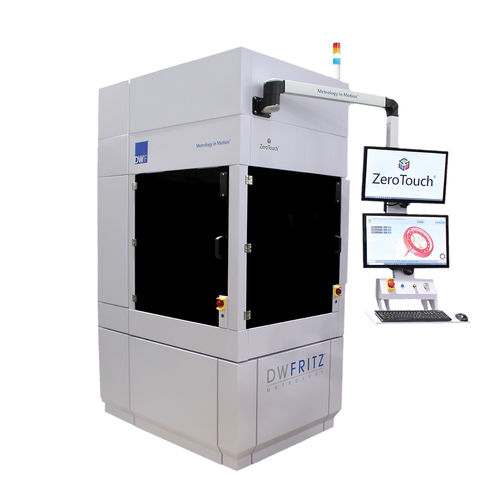

Defect inspection machine ZeroTouch®3Dsurfacefor the automotive industry

Add to favorites

Compare this product

Characteristics

- Technology

- 3D

- Applications

- surface

- Sector

- for the automotive industry, for the electronics industry

- Other characteristics

- defect, high-resolution, high-throughput, non-contact

Description

The ZeroTouch® Linear Metrology System is a high-speed, non-contact linear inspection system ideal for measuring linear-shaped parts such as hip stems and aerospace blades as well as smaller parts such as inserts faster than traditional methods.

FEATURES AND BENEFITS

Developer coating not required to capture shiny surfaces

Configurable for both in-line or near-line use

System functions in manual or fully automatic mode

Allows for 100% inspection of parts leading to process and quality improvements

Supports a wide range of dimensions and weights

Small footprint allows for optimal usage of production space

Micron-level precision and accurate analysis with dense point cloud

Scans 100% of part in under 60 seconds

Rapid Data Capture & Analysis

Using application-based advanced sensors, the system can capture millions of data points per second, with variable data density levels, executing part inspection plans and performing all critical to quality measurements faster than tactile methods.

High-Volume Production

ZeroTouch® performs all measurements that previously required multiple systems, reducing the overall metrology footprint, and enabling in-line inspection on high-speed production lines where 100% part measurement is required.

Upstream Process Improvement

Through industry proven and recognized analytics software, parts can be analyzed by comparing point cloud scans with nominal CAD models and GD&T controls. Statistical process control (SPC) data can drive warnings to reduce variability and scrap.

Industries and Applications

Aerospace

Automotive & E-Mobility

Orthopedic Implants

Precision Manufacturing

VIDEO

Catalogs

Related Searches

- Inspection machine

- Defect inspection machine

- Measurement inspection machine

- Inspection machine for the electronics industry

- Surface inspection machine

- High-speed inspection machine

- High-resolution inspection machine

- 3D inspection machine

- Non-contact inspection machine

- Inspection machine for the automotive industry

- Gear inspection machine

- Inspection machine for the aerospace industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.