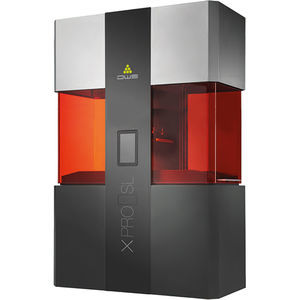

Jewelry 3D printer XFAB 2500HD SLAindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- SLA

- Applications

- industrial, for jewelry

- X travel

180 mm

(7.09 in)- Y travel

180 mm

(7.09 in)- Layer thickness

Min.: 10 µm

Max.: 100 µm

- Weight

31 kg

(68.34 lb)

Description

XFAB 2500HD is the perfect tool for professional applications in jewellery to produce models for direct casting and rubber moulding.

It is provided with the proprietary software Nauta®+, that allows to modify supports, to alter the orientation and the position of objects for best 3D printing, thus maximizing the quality of surfaces.

The printer features also the Fictor® software, that allows to manually customize the parameters of DWS materials based on the user’s know-how.

XFAB 2500HD is addressed to small goldsmiths, designers and to those who need to produce a wide variety of models in high resolution, from solid to fine detailed models, for direct casting and rubber moulding.

The smart cartridges for the XFAB series have been designed to ensure safety, a quick material change and the cutting of time for material filling and replacements.

Thanks to the automatic extrusion mechanism, no manual intervention is required and risks of accidental leaks are eliminated.

XFAB 2500HD works with professional grade materials like Fusia DC710, Fusia DC800 and Fusia DC900.

The BlueEdge® laser developed in-house by DWS is accurate, precise and calibrated to obtain smooth surfaces requiring no further finishing. It is long lasting and needs no maintenance or adjustments.

Main Features

•Fast and precise stereolithographic printer

•“Plug & Play” system

•Material developed and produced by DWS

•TTT System - Tank Translation Technology that reduces wear and tear of tanks

Catalogs

BROCHURE J

30 Pages

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- High-speed 3D printer

- High-performance 3D printing machine

- ABS 3D printing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Table-top 3D printer

- Resin 3D printer

- SLA 3D printing machine

- Mold manufacturing 3D printer

- Color 3D printer

- Jewelry 3D printer

- Hybrid 3D printer

- Wax 3D printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.