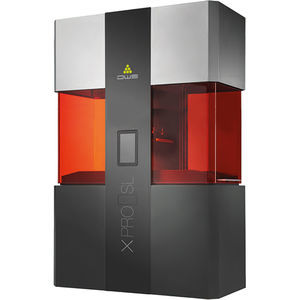

SLA 3D printer 029XABSindustrialfor jewelry

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- ABS

- Technology

- SLA

- Applications

- industrial, for jewelry

- Other characteristics

- high-speed

- X travel

150 mm

(5.91 in)- Y travel

150 mm

(5.91 in)- Z travel

200 mm

(7.87 in)- Layer thickness

Min.: 10 µm

Max.: 100 µm

- Weight

150 kg

(330.69 lb)

Description

029X is a high-speed,high-precision SLA 3D printer for rapid manufacturing in the jewellery industry. Specifically developed for medium and large-sized jewellery workshops, it is ideal for companies demanding a top reliable printer with a large printing area that can produce pieces of the highest quality, precision and resolution, in big quantities. 029X can produce up to 270 pieces per day (depending on the complexity) to an extremely high level of detail, including smooth surfaces, undercuts, cavities, and filigrees, ensuring the greatest freedom when designing. With extremely low running and maintenance costs, the printer has been designed to operate continuously, always ensuring the maximum reliability and consistency. Together with the integrated Nauta®+ software that automatically generates the support structures, the system is compatible with the entire range of materials developed by DWS for jewellery applications. Two special optional modules are available for the print of clusters for direct casting (XCluster®*) and for the print of clusters of already linked chains (XCluster®* Chain).

029X is also available in the versions 029XJ, that stands out for its 20 micron laser spot and 029XHR with its 20 micron high resolution laser spot, ideal for enterprises producing highly detailed objects, filigrees, micro-pavé, griffe.

Main Features

•Print precision and resolution at its highest levels on the market

•Ideal for the creation of considerable quantities of models

•TTT System – Tank Translation Technology that optimizes wear and tear of tanks

•Very low costs for operation and maintenance

Catalogs

BROCHURE X

27 Pages

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- High-speed 3D printer

- High-performance 3D printing machine

- ABS 3D printing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Table-top 3D printer

- Resin 3D printer

- SLA 3D printing machine

- Mold manufacturing 3D printer

- Color 3D printer

- Jewelry 3D printer

- Hybrid 3D printer

- Wax 3D printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.