- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

AC servomotor 0915059 seriesasynchronous230 V400 V

Add to favorites

Compare this product

Characteristics

- AC/DC

- AC

- Type

- asynchronous

- Voltage

- 400 V, 230 V

- Protection class

- corrosion-resistant

- Configuration

- stainless steel

- Applications

- for cutting machine

- Power

1.5 kW, 3.5 kW

(2.039 hp, 4.759 hp)

Description

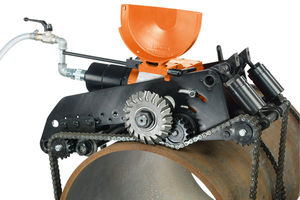

for pipe cold cutting machine

For heavy wall cutting and beveling

Shock proof and corrosion proof

Big bright screen

Emergency stop

Speed, torque and current are controlled during the cutting & beveling process

To get the best performance in the machining process, many parameters are important: material, outside diameter, wall thickness, weld prep type, operator skills etc.. Usually the machines were equipped with pneumatic or hydraulic motors. Even though these drives deliver tremendous power, but due to lack of parameter control and information in the process the operator had to be very skilled and trained. Nowadays, the cold cutting machines can be equipped with electrical driven servo drive motors, where speed, torque and current can be displayed, measured and stored during the cutting process.

Additionally, this motor does not slow or strain under load. With this intelligent controller, the operator can work perfectly with different materials and pipe characteristics onsite, always choosing the correct settings by help of the controller. The servo drive for the pipe cold cutting machines is delivered with geared motor and controller. It is available in a 230 V and 400 V version, furthermore, shock proof and corrosion proof with stainless steel housing, a big bright screen and emergency stop.

VIDEO

Catalogs

No catalogs are available for this product.

See all of DWT GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.