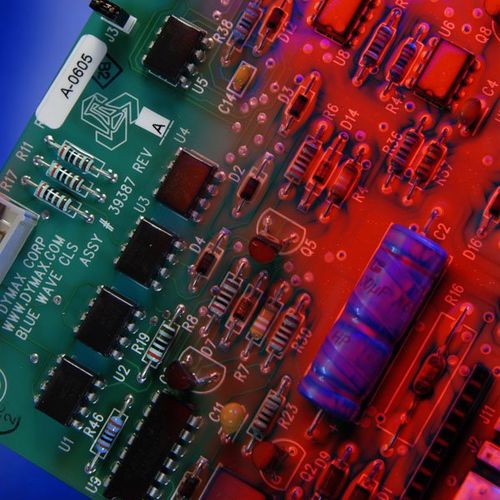

DYMAX’s broad range of one-part, solvent-free electronic materials cure in seconds upon exposure to UV/visible light. They do not emit HAPs or VOCs upon cure. DYMAX UV curable materials are used in a wide variety of applications for circuit protection and electronic assembly. The products are electrically insulating and are designed for various operations including conformal coating, encapsulation, bonding, keypad coatings, thermal management, and masking. IPC approved, MIL-I-46058C and UL listed self-extinguishing grades are available. Most products are available in multiple-viscosity grades, so the material flow may be tailored to the individual application.

DYMAX UV curable conformal coatings may be applied over the entire PCB surface or discreet areas to provide complete protection from harsh environments or chemical exposure. Multiple shadowed-area cure options are available. UV curable encapsulants protect components on rigid or flexible boards to -40°C. UV curable peelable maskants are designed for manual or fully automated masking of printed circuit boards prior to wave solder or reflow operations