Acrylic adhesive for metalsingle-componentindustrial

Add to favorites

Compare this product

Characteristics

- Chemical composition

- acrylic

- Type of substrate

- for metal

- Number of components

- single-component

- Applications

- industrial

Description

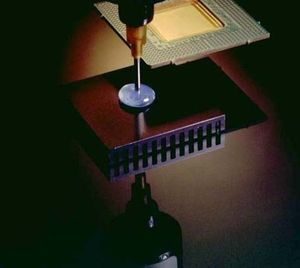

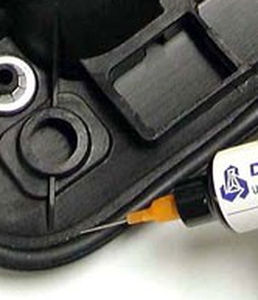

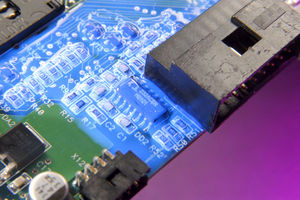

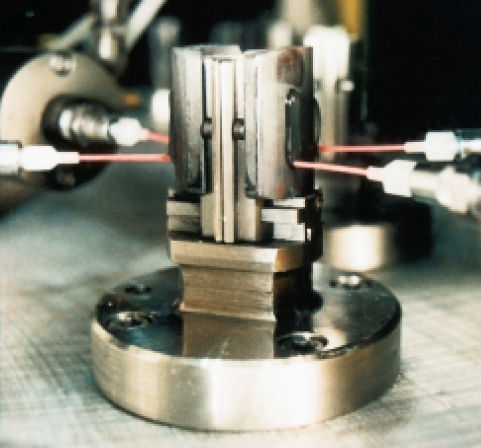

Structural Adhesives and Epoxies for Metal Bonding, Magnet Bonding, and Motor Assembly Applications

Acrylic and methacrylic acid-free, activator-curing structural adhesives brought about the technology revolution, known as "cold bonding", to the magnet and motor assembly industries. These structural adhesives are ideal for choke and transformer bonding, DC motor assembly, alternator, and flywheel applications, tacking, unitizing, ruggedizing, sealing, and shallow potting. This revolutionary resin chemistry has drastically shortened assembly times and saved space, labor, and regulatory compliance costs to make automation easier for manufacturers.

DYMAX 600 and 800 series structural adhesives fixture in seconds, are non-corrosive, non-flammable, and suitable for harsh environments. Additionally, some products cure upon exposure to UV/Visible light or heat. Automated systems are available to conveniently apply adhesives and activators to substrates. The 600 and 800 series structural adhesives for magnet and motor assembly develop strength to 500 psi in seconds, with ultimate bond strengths to 3,500 psi, between opaque surfaces with activator.

Catalogs

No catalogs are available for this product.

See all of DYMAX Europe GmbH‘s catalogsRelated Searches

- Single-component glue

- Metal glue

- Industrial glue

- Plastic glue

- Glass glue

- Epoxy adhesive

- Dispersion adhesive

- Electronic glue

- Conductivity adhesive

- Curing unit

- UV curing unit

- Cyanoacrylate glue

- High-temperature adhesive

- Automotive glue

- Polyurethane glue

- UV-polymerized adhesive

- Thermally-conductive adhesive

- Medical adhesive

- Acrylic adhesive

- Polymerization adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.