Dilute phase pneumatic conveying system LDV 4000aspirationpowder

Add to favorites

Compare this product

Characteristics

- Type

- dilute phase, aspiration

- Product applications

- powder

Description

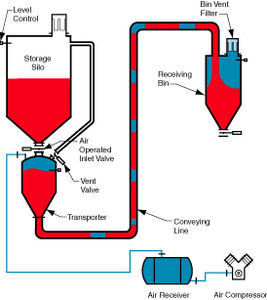

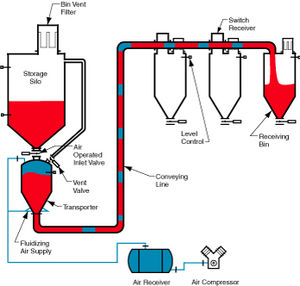

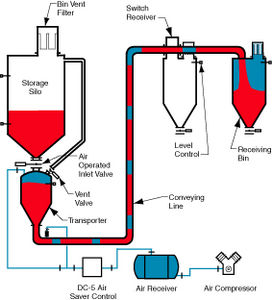

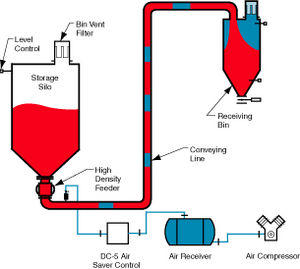

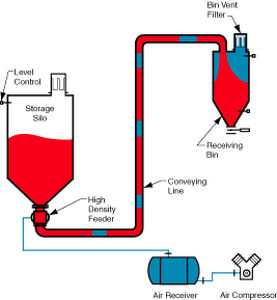

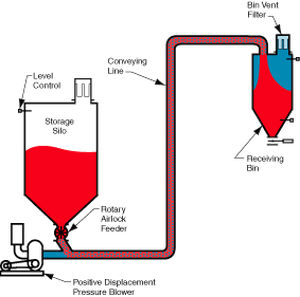

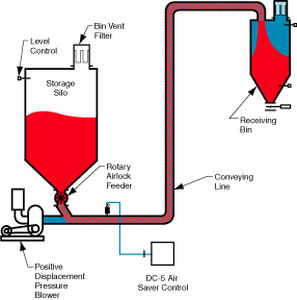

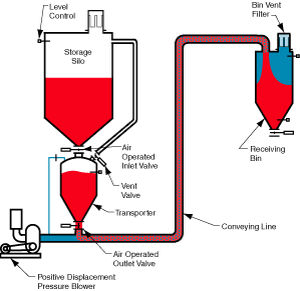

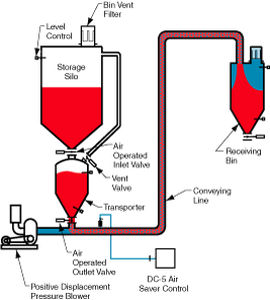

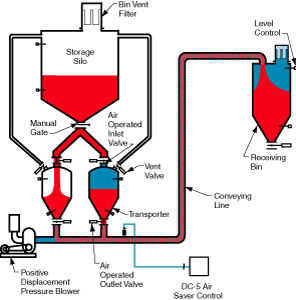

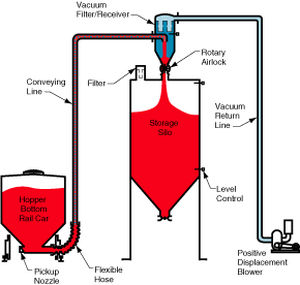

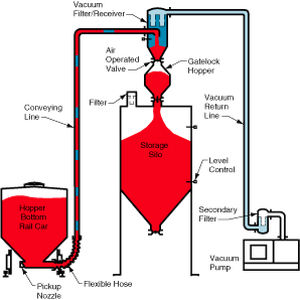

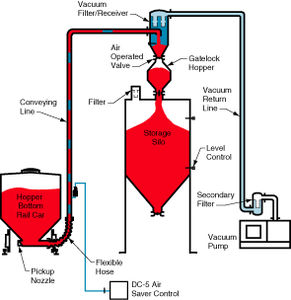

The LDV 4000 Vacuum Concept Conveying System is a dilute phase, medium to high velocity, low pressure, continuous vacuum conveying system for shorter distances. It is generally used to convey low to high density, non-abrasive and semi-abrasive materials. Examples include iron oxide, titanium dioxide, silica flour, cement, and limestone.

Typical conveying velocities are 1000 to 3000 feet per minute (5 m to 15 m/sec) and vacuum conveying pressures of up to 15 inches (381 mm) of Mercury (hg).

The material is fed into the conveying line on a continuous basis by vacuum. DC-5 Air Saver technology is used to minimize and optimize the low pressure supply air which is supplied by a low pressure positive displacement blower. The system includes a vacuum pickup nozzle, a vacuum filter receiver, a rotary airlock feeder and a positive displacement blower.

Catalogs

Related Searches

- Rail conveyor

- Transporting conveyor

- Horizontal rail conveyor

- Grinding mill

- Feeder

- Horizontal grinding mill

- Relief valve

- Vertical grinding mill

- Food lump breaker

- Screw conveyor

- Roller grinding mill

- Pilot-operated relief valve

- Pneumatic conveying system

- Flexible conveyor

- Big bag station

- Gravity conveyor

- Air conveyor

- Diverter valve

- Powder pneumatic conveying system

- Motorized feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.