- Metrology - Laboratory

- Metrology and Test Equipment

- Performance testing machine

- Dynamometer Equipment (China) Co. Limited

- Products

- Catalogs

- News & Trends

- Exhibitions

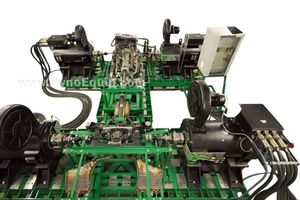

Durability testing machine performancegearbox

Add to favorites

Compare this product

Characteristics

- Test type

- durability, performance

- Test material

- gearbox

Description

Front wheel drive test. Shortening vehicle development cycles is only achievable by carrying out test as early as possible at the testbed without having a real vehicle prototype. Therefore, it is mandatory to test available components as soon as possible to improve durability, functionality and performance. Under the unproven maturity of combustion engine, the latest front wheel drive test bench solution of Front Engine Front-Wheel Drive (FF) powertrain can effectively evaluate any kind of transmission combination. The test bed can also be prepared to test powertrains of Hybrid Electrical Vehicles (HEV).

The classical powertrain consists of internal combustion engines (ICE) and transmissions, which are connected by mechanical elements. These components must be verified with respect to durability, functionality and performance.

The key features of this configuration are a low-inertia drive AC dynamometer which replaces the combustion engine. The drive AC dynamometer simulates the engine’s transient behaviour and reacts to control unit commands. Engine firing pulses can also be simulated if necessary. The drive AC dynamometer can be removed to allow tests with the combustion engine. This second configuration allows a joint testing of combustion engine and transmission. Realistic loading of the front wheel drive powertrain test with AC dynamometer like in vehicle tests on the road is possible. Both configurations lead to reproducible test results under well-known constant environmental conditions.

Other Dynamometer Equipment (China) Co. Limited products

AC dynamometers

Related Searches

- Test machine

- Test stand

- Durability test machine

- Performance test machine

- Torque test stand

- Performance test stand

- Force test stand

- Flow test stand

- Fatigue test stand

- Engine test bench

- Vehicle test stand

- Gearbox test stand

- Endurance test stand

- Electric motor test stand

- Mechanical drive test stand

- Electrical and mechanical test stand

- Brake test stand

- Test stand with climatic chamber

- Gearbox testing machine

- Water pump test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.