- Metrology - Laboratory

- Metrology and Test Equipment

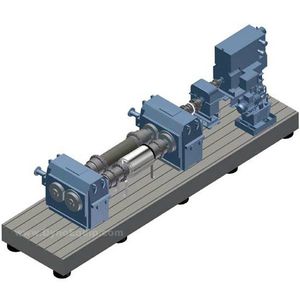

- Performance test bench

- Dynamometer Equipment (China) Co. Limited

- Products

- Catalogs

- News & Trends

- Exhibitions

Performance test bench for electric motors

Add to favorites

Compare this product

Characteristics

- Test type

- performance

- Test material

- for electric motors

Description

Research into the maximum performance of hybrid vehicle traction has led to the development of high-speed and high-torque electric motors that require specially designed AC dynamometer.

Dyno Equip offers the AC dynamometer motor with outstanding maximum torque of 500Nm and speed up to 20,000rpm that is combined with inertia lower than 0.1kgm2 for high vehicle dynamic simulation. The AC dynamometer has been achieved through the development of a hybrid hydraulic bearing technology that enables high speeds, while reducing vibration to 2mm per second at 20,000rpm. The Dyno Equip AC dynamometer may replace the real one for drivetrain and gearbox testing.

The latest application of this range of AC dynamometer is in a modular transmission test bench for vibration analysis and conformity of production. The three-motor test bench (with one input AC dynamometer and two output AC dynamometers) features a quick release specimen pallet, enabling three types of test configurations with easy and quick installation. Traditional transmission dynamometer, as well as high-speed powertrain dynamometer and driveline dynamometer for electric vehicles, can be made. For electric vehicle driveline testing, AC dynamometer with ultra low motor rotor inertia of guarantees achievement of high dynamic performance.

Electric vehicle motor inverter dynamometer highlight

Energy-efficient permanent magnet synchronous motor AC dynamometer 250kW, 500Nm, 20,000 rpm (Overload torque: 600Nm)

Very low vibrations (Less than 2 mm per second)

Selection between type-specific inverter and integrated universal power electronic unit before test start

Other Dynamometer Equipment (China) Co. Limited products

Testing solutions

Related Searches

- Test machine

- Test stand

- Durability test machine

- Performance test machine

- Torque test stand

- Flow test stand

- Force test stand

- Fatigue test stand

- Performance test stand

- Engine test bench

- Vehicle test stand

- Gearbox test stand

- Endurance test stand

- Electric motor test stand

- Brake test stand

- Electrical and mechanical test stand

- Mechanical drive test stand

- Test stand with climatic chamber

- Gearbox testing machine

- Water pump test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.