- Metrology - Laboratory

- Metrology and Test Equipment

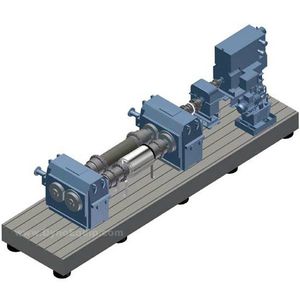

- Torque test bench

- Dynamometer Equipment (China) Co. Limited

- Products

- Catalogs

- News & Trends

- Exhibitions

Torque test bench fatiguefor automotive shafts

Add to favorites

Compare this product

Characteristics

- Test type

- torque, fatigue

- Test material

- for automotive shafts

Description

The fatigue tests with rotary actuator can be performed on automotive propeller shafts, axle shafts, axle housings, crankshafts, ball joints, couplings and other rotary parts using in automobiles, aircraft, carriages, electric motors and machines. The fatigue tests can perform static load and dynamic load which should be configured independently.

Electro-hydraulic servo test tables bench with angle and (or) torque control are used for static, quasi-static and fatigue component testing under pure torque loads. The torque generating by a rotary actuator is associated with the component-under-test through a rigid coupling. This structural design can basically eliminate the load superposition by bent loading and lateral force and the impact of misalignment. Through the fixture adapter, the specimen fixture can be quickly and easily connected. It is suitable for a variety of alternating torque applications. Various measurement data can be detected by encoder, angle sensor, torque sensor and pressure sensor.

Other Dynamometer Equipment (China) Co. Limited products

Testing solutions

Related Searches

- Test machine

- Test stand

- Durability test machine

- Performance test machine

- Torque test stand

- Performance test stand

- Force test stand

- Flow test stand

- Fatigue test stand

- Engine test bench

- Vehicle test stand

- Gearbox test stand

- Endurance test stand

- Electric motor test stand

- Mechanical drive test stand

- Electrical and mechanical test stand

- Brake test stand

- Test stand with climatic chamber

- Gearbox testing machine

- Water pump test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.