Differential pressure flow meter HBP pitot tubevolumefor air

Add to favorites

Compare this product

Characteristics

- Technology

- differential pressure, pitot tube

- Type

- volume

- Fluid

- for air, for exhaust gas, for flue gas, for dust-laden gases

- Installation

- flange

- Material

- stainless steel, aluminum

- Applications

- industrial

- Other characteristics

- compact, high-accuracy, with mass flow controller, with pressure measurement, with flow conditioner

Description

Air flow measurement is most accurate in straight duct runs where air flow can be evenly profiled across the duct at the point of measurement and where no turbulent, reverse, or cyclonic flow patterns are present. Typically, it can take as much as 10 diameters of straight duct run to eliminate turbulent or reverse flow, while it can take as much as 30 diameters of straight duct run to eliminate cyclonic flow. If you do not have the proper amount of straight duct run present to accurately measure your air flow, some type of flow conditioner is required.

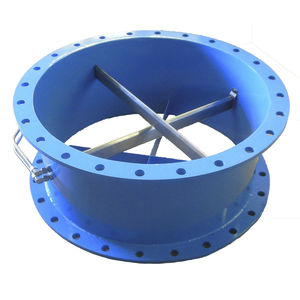

The HBP - High Beta Process Flow Conditioner is ideally designed for industrial process applications where the expansive straight duct runs needed for accurate flow measurement are not present. Perfect for new or for retrofit applications, the HBP is designed for installations with relatively no straight duct runs upstream or downstream and eliminates cyclonic, turbulent and reverse flow at the point of measurement. The HBP consists of a flanged spool section, a converging duct section, a set of straightening vanes and an array of VAP Pitots. The HBP ensures an accurate differential pressure output that provides precise air flow measurement for tighter control of your process.

DUCT SECTION - 24" .707 SS High Beta duct section, available in diameters up to 36".

ACCURACY - Accuracy to within ±0.5% and repeatability to within ±0.1%. Testing certification in an AMCA rated test chamber is available.

BASIC INSTALLATION - Includes a flanged duct section for easy installation, while the contained pitot array is internally manifolded and connected via through-wall fittings.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Flowmeter

- Volume flowmeter

- Liquid flowmeter

- Pressure transmitter

- Analog pressure transmitter

- Gas flowmeter

- Stainless steel flowmeter

- Industrial flowmeter

- Stainless steel pressure transmitter

- Relative pressure transmitter

- In-line flowmeter

- Precision flowmeter

- Compact flowmeter

- Mass flowmeter

- Gas pressure transmitter

- Absolute pressure transmitter

- Flowmeter with display

- Digital flowmeter

- Flange flowmeter

- Process pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.