Gravimetric flow meter LDMvolumefor bulk materialsin-line

Add to favorites

Compare this product

Characteristics

- Technology

- gravimetric

- Type

- volume

- Fluid

- for bulk materials

- Installation

- in-line, flange, vertical

- Material

- stainless steel, aluminum

- Communication

- 4-20 mA, analog output, digital output, with pulse output

- Supply voltage

- AC

- Applications

- for bulk materials, for low-density materials

- Other characteristics

- compact, high-accuracy, maintenance-free

- Mass flow rate

Min.: 100 lb/h

(45.36 kg/h)Max.: 1,000,000 lb/h

(453,592.37 kg/h)- Volumetric flow rate

Min.: 8.44 ft³/min

(0.239 m³/min)Max.: 562.4979 ft³/min

(33,749.8738 m³/min)- Repeatibility

0.1 %

Description

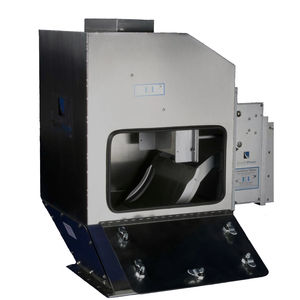

The CentriFlow Meter from Eastern Instruments is a Solid Particle Mass Flow Meter that is durable, accurate, maintenance-free, compact, and cost-effective.

The CentriFlow Light Density Meter (LDM) is a specialized version of the CentriFlow Meter designed to measure low density materials (typically products 10 lb/ft3 or less). The radius of the Measurement Pan is twice that of the Standard CentriFlow Meter. By enlarging the Measurement Pan's radius, the LDM is able to accommodate low-density, bulky, large-particle materials such as tobacco (whole leaf, strip, stems, processed leaf, etc.), wood chips, leafy vegetables and many other similar materials. The LDM is available in a variety of sizes to accommodate almost any product that is being fed from a belt or vibratory conveyor. Due to the bulky nature and the larger particle size of products typically fed through the LDM Meter, the meter is typically installed in the In-Line Feed orientation only.

IN LINE ORIENTATION

Because many of the products that are measured with the LDM Meter are large particle materials, such as whole leaf tobacco, wood chips or shreds, or even shredded plastic bags, the meter is typically installed in the In-Line orientation to prevent choking or clogging of the meter. The In-Line orientation ensures that there is no choke point within the flow of material. In the In-Line Orientation, product will flow off of the belt, over a transition and through the CentriFlow Meter which will be tilted backwards at up to 20 degrees. The product will then, continue flowing in its original direction.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

International Powder and Bulk Solids Conference and Exhibition

29 Apr - 01 May 2025 Rosemont, IL (United States) Stand 2333

More information

Related Searches

- Flowmeter

- Volume flowmeter

- Liquid flowmeter

- Pressure transmitter

- Analog pressure transmitter

- Gas flowmeter

- Stainless steel flowmeter

- Industrial flowmeter

- Stainless steel pressure transmitter

- Relative pressure transmitter

- In-line flowmeter

- Precision flowmeter

- Compact flowmeter

- Mass flowmeter

- Absolute pressure transmitter

- Digital flowmeter

- Flowmeter with display

- Gas pressure transmitter

- Flange flowmeter

- Sensitive element pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.