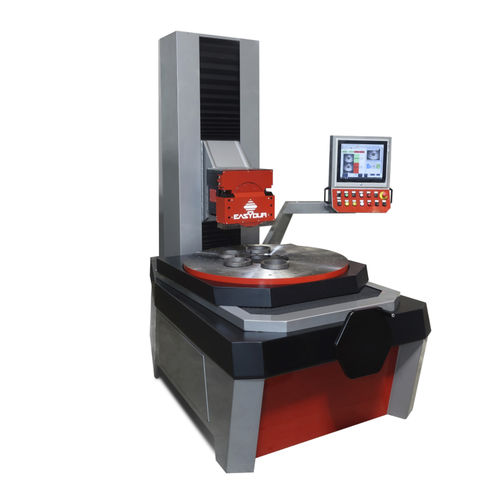

INTEGRAL ROTARY is a hardness tester designed to perform hardness tests on small and medium sized specimens. The advantage of this solution is the possibility to speed up hardness testing, thanks to the possibility of positioning several specimens on the motorized rotary table. Ideal for companies that produce batches of thousands of pieces and must therefore test their hardness in series.

INTEGRAL ROTARY is equipped with the EASYDUR revolver head, consisting of the following slots:

Laser pointer (for finding the correct test point)

Workpiece press (for clamping)

Milling Slots (for surface preparation, with adjustable depth and RPM)

Slot with indenter (for making the Brinell and HRC indentations)

Slot with autofocus camera (for reading the indentation)

Data acquisition and hardness calculation

On-screen display of results

Archiving of images and results with corresponding statistics

This is a real 4.0 hardness tester, as in order to make the work of the operator as easy as possible it is equipped with a motorized rotary table that can also move horizontally (on the X axis), to ensure correct centering of all the pieces to be tested. By setting a fully automatic cycle (e.g. 3 tests at 120°, 4 at 90°, etc.) the motorized rotary table allows to carry out the tests by programming the test points, working with the highest precision, considerably reducing the working time and eliminating the possibility of human error.

Main features:

Max. load 3,000kg

Load resolution: 100,000 divisions

5 MegaPixel Camera