- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

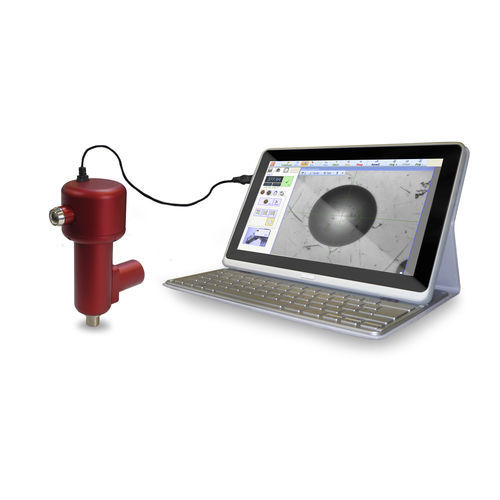

Brinell indentation hardness tester EASYBRINELLportable

Add to favorites

Compare this product

Characteristics

- Type

- Brinell

- Mounting

- portable

- Load

Max.: 3,000 kgf

Min.: 1 kgf

Description

Portable probe for automatic image analysis for Brinell tests (1-3000Kg), repeatability +/- 0.1 HBW with instrument management by a built-in tablet, selection of loads and automatic test scales from a menu, automatic measurement. The absolute measurement is already valid at the first test.

“Precise measurements in all conditions”

It is possible to perform tests on untreated or uncleaned surfaces, ideal for use in foundries and forging workshops. The Brinell indentation is read by a built-in camera and monitor with very high definition electronic measurement, with precision 1 micron and enlargements from 20x to 400x.

The entire measurement cycle is automatic, from auto-focus to light adjustment. The image of the indentation and of the surface of the test piece can be exported. It is also possible to export the test certificate, with statistical analysis, storage of the image and transmission of images over a network. Large memory for storing data and tests, with archive management. The instrument is built with the certification requirements of the calibration bodies.

SOFTWARE

The probe is managed using a table with Windows 8 operating system, colour touch screen and a software program developed internally by EASYDUR, with a guiding menu that enables the operator to follow the various phases of the test which are performed in sequence automatically: choice of tests, rapid and precise Brinell measurements; storage of the images of the piece and of the indentations, dimensional measurements.

The complete statistical program supplies diagrams and histograms and a vast data archive, as well as the printing of test certificates and the export of data with a network board.

VIDEO

Catalogs

Related Searches

- Test machine

- Measuring machine

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Laboratory test machine

- Precision test machine

- Rockwell indentation hardness tester

- Brinell indentation hardness tester

- Electromechanical test machine

- Vickers indentation hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.