- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Compression test machine EASYROTARYautomaticfor springsmechanical

Add to favorites

Compare this product

Characteristics

- Test type

- compression

- Operating mode

- automatic

- Test material

- for springs

- Technology

- mechanical

Description

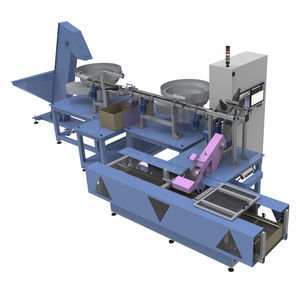

Automatic system for checking 100% of spring production. Possibility of including multiple presetting stations, compression tests, optical measurement stations, packaging stations, painting stations, multi-way selectors.

Automatic system for pressing and measuring ground and non ground springs (100% check), with manual or automatic loading (with vibrator or robot). It can be completely customised to meet the needs of each customer, including several stations and multiple load tests, optical measuring stations and multi-way selectors. The instrument is equipped with a rotating table with pneumatic grippers that prevent the spring from rubbing against the bushings. The instrument is managed via PLC and PC (in case of load test station and/or optical dimensional control), allowing the creation of customised work programs as well as the complete management of batches and working times.

The solution can be configured with:

• Multiple presetting stations

• Multiple stations for compression tests

• Optical stations for high-precision dimensional measurements

• Multi-way selectors

• Painting stations

• Packaging solutions

The software, developed in-house by EASYDUR, allows the internal management of the archives, statistics and certificates in Excel format, therefore fully modular and customisable by the customer himself. Software meets industry standard 4.0

OTHER CHARACTERISTICS:

• test diagram

• easily readable and exportable ASCII archive

• elasticity and rigidity diagrams

• integrated network card, USB

• electronic handwheel for manual movements with precision 0.005 mm and for archive management

• media, sigma, Gaussian curves, CP, CPK…

VIDEO

Catalogs

No catalogs are available for this product.

See all of EASYDUR SRL‘s catalogsRelated Searches

- Test machine

- Measuring machine

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Compression test machine

- Benchtop indentation hardness tester

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Laboratory test machine

- Rockwell indentation hardness tester

- Precision test machine

- Electromechanical test machine

- Brinell indentation hardness tester

- Optical measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.